20

DR

®

PRO XL-DRT

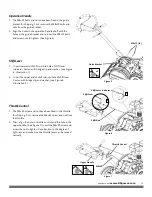

OUTER SIDE SHIELDS

To protect small plants from being buried while tilling, the back edges of the

outer side shields are slotted so that the shields can be raised for deep

tilling and lowered for shallow tilling. (See Figure 12) To move the shield to

the desired position (both sides), loosen nut A and nut B, move the shield,

and retighten the nuts.

STOPPING THE TINES AND DRIVE

Release drive control bar to stop movement.

Move shift lever to “N” (neutral) position.

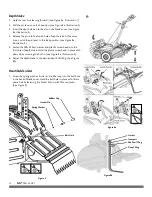

TRANSPORT AROUND THE YARD

Release the depth stake pin. Move the depth stake down to the second top hole for transporting the tiller. Place depth stake pin

in hole of depth stake to lock in position. This prevents tines from scuffing the ground.

Place shift lever indicator in “F” (forward) position for transporting.

Hold the drive control bar against the handle to start tiller movement. Tines will not turn.

Move throttle control to desired speed.

IDLE SPEED

Set the throttle control lever to the SLOW position to reduce stress on the engine when work is not being performed. Lowering the

engine speed will help extend the life of the engine, as well as conserve fuel and reduce noise level.

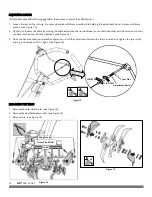

STOP ENGINE

To stop the engine in an emergency, simply turn the engine switch to the OFF position. Under normal conditions, use the

following procedure:

1.

Move the throttle lever to the SLOW (

) position.

2.

Let the engine idle for one or two minutes.

3.

Turn the engine switch to the OFF position.

4.

Turn the fuel valve lever to the OFF (

) position.

Figure 12

CAUTION: Before lifting or transporting, allow engine and muffler to cool. Disconnect sparkplug wire. Drain gasoline from fuel

tank.

Sudden stopping at a high speed under a heavy load is not recommended. Engine damage may result.

Do not move the choke control to CLOSE to stop the engine. Backfire or engine damage may occur.