OPEN

CLOSED

OPEN

CLOSED

OUTLET

INLET

B

A

OUTLET

INLET

OPEN

CLOSED

CLOSED

OPEN

B

A

The Pro-Flo

®

patented air distribution system incorporates

three moving parts: the air valve spool, the pilot spool, and

the main shaft/diaphragm assembly. The heart of the system

is the air valve spool and air valve. As shown in Figure 1, this

valve design incorporates an unbalanced spool. The smaller

end of the spool is pressurized continuously, while the large

end is alternately pressurized and exhausted to move the

spool. The spool directs pressurized air to one chamber

while exhausting the other. The air causes the main shaft/

diaphragm assembly to shift to one side — discharging liquid on

one side and pulling liquid in on the other side. When the shaft

reaches the end of its stroke, it actuates the pilot spool, which

pressurizes and exhausts the large end of the air valve spool. The

pump then changes direction and the same process occurs in the

opposite direction, thus reciprocating the pump.

MAIN SHAFT

CENTER BLOCK

PILOT

SPOOL

SMALL END

END CAP

LARGE END

AIR VALVE SPOOL

MUFFLER

MUFFLER PLATE

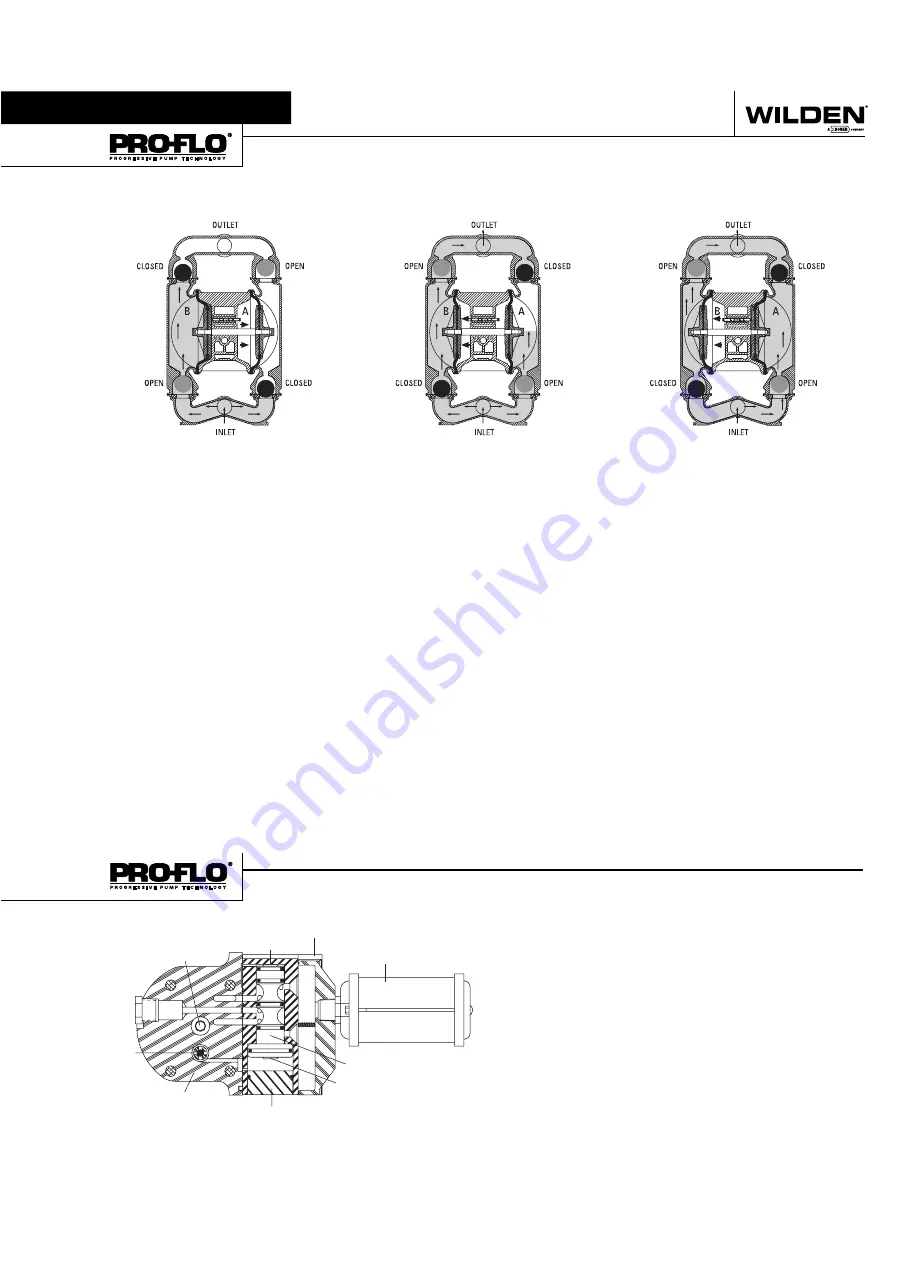

The Wilden diaphragm pump is an air-operated, positive displacement, self-priming pump. These drawings show fl ow pattern through

the pump upon its initial stroke. It is assumed the pump has no fl uid in it prior to its initial stroke.

Figure 1

OUTLET

INLET

OPEN

CLOSED

CLOSED

OPEN

B

A

FIGURE 1

The air valve directs pressurized

air to the back side of diaphragm A. The

compressed air is applied directly to the

liquid column separated by elastomeric

diaphragms. The diaphragm acts as

a separation membrane between the

compressed air and liquid, balancing the

load and removing mechanical stress from

the diaphragm. The compressed air moves

the diaphragm away from the center block

of the pump. The opposite diaphragm is

pulled in by the shaft connected to the

pressurized diaphragm. Diaphragm B is on

its suction stroke; air behind the diaphragm

has been forced out to the atmosphere

through the exhaust port of the pump.

The movement of diaphragm B toward the

center block of the pump creates a vacuum

within chamber B. Atmospheric pressure

forces fl uid into the inlet manifold forcing

the inlet valve ball off its seat. Liquid is free

to move past the inlet valve ball and fi ll the

liquid chamber (see shaded area).

FIGURE 2

When the pressurized

diaphragm, diaphragm A, reaches the

limit of its discharge stroke, the air valve

redirects pressurized air to the back

side of diaphragm B. The pressurized air

forces diaphragm B away from the center

block while pulling diaphragm A to the

center block. Diaphragm B is now on its

discharge stroke. Diaphragm B forces the

inlet valve ball onto its seat due to the

hydraulic forces developed in the liquid

chamber and manifold of the pump. These

same hydraulic forces lift the discharge

valve ball off its seat, while the opposite

discharge valve ball is forced onto its seat,

forcing fl uid to fl ow through the pump

discharge. The movement of diaphragm

A toward the center block of the pump

creates a vacuum within liquid chamber A.

Atmospheric pressure forces fl uid into the

inlet manifold of the pump. The inlet valve

ball is forced off its seat allowing the fl uid

being pumped to fi ll the liquid chamber.

FIGURE 3

At completion of the stroke, the

air valve again redirects air to the back side

of diaphragm A, which starts diaphragm

B on its exhaust stroke. As the pump

reaches its original starting point, each

diaphragm has gone through one exhaust

and one discharge stroke. This constitutes

one complete pumping cycle. The pump

may take several cycles to completely

prime depending on the conditions of the

application.

Right Stroke

Mid Stroke

Left Stroke

S e c t i o n 3

H O W I T W O R K S — P U M P

H O W I T W O R K S — A I R D I S T R I B U T I O N S Y S T E M

WIL-10161-E-01

3

WILDEN PUMP & ENGINEERING, LLC