Installation

Technical Manual

35

HAC Standard fixing - 02/2018

dormakaba c-lever pro

4.11

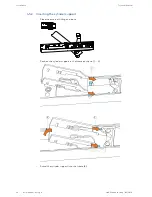

Preparing the internal fitting

NOTICE

Damage to the union nut

When loosening the union nut, make sure it does not touch the threaded pin.

•

Using the multitool, loosen the union nut from the internal fitting (>360°).

>360°

•

With locking cylinder: If necessary, loosen the forend locking stud.

•

Push the cover out of the groove (1), pull it forwards slightly (2) and turn (3).

1.

2.

3.

If the c-lever pro is already programmed, the clock settings are lost approx. 45 seconds after

the battery is removed.

•

Push the battery holder in the direction shown (1.) and at the same time swivel it for-

wards (2.).

1.

2.