- 53 -

LP Engine G430 (3.0L)

Igntion System

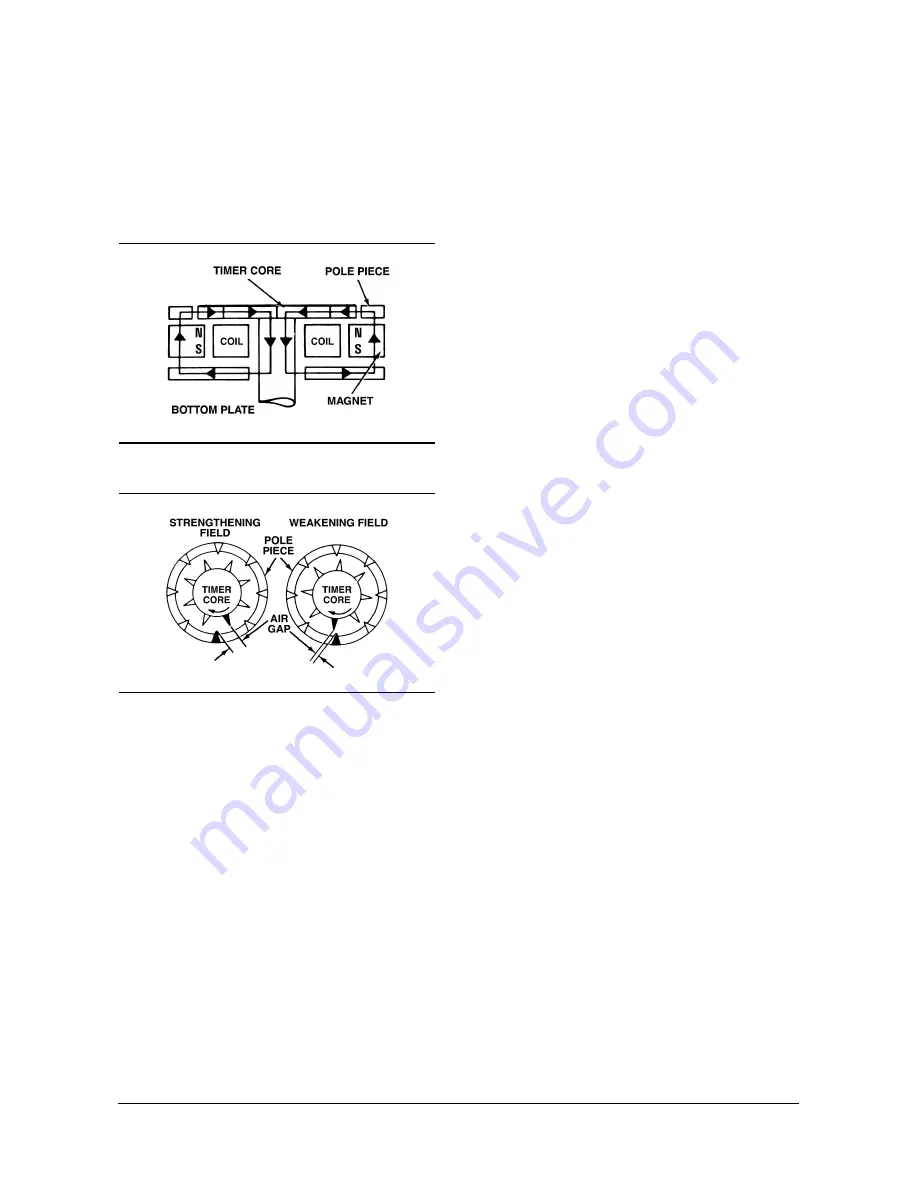

Magnetic Flux Path

A timer core on the main shaft of the distributor has

external teeth which align with an equal number or

pole piece teeth.

Figure 6-4 Magnetic Flux Path

Figure 6-5 Magnetic Field Strength Variation

The magnetic pickup assembly, by the varying

magnetic field around the pickup coil, produces

electric current in the pickup coil by electromagnet

induction. As the timer core rotates past the pole

piece, the air gap between timer core and pole piece

teeth varies. Since air is not a good path magnetic flux

to travel through, the magnetic field relatively weak

when the teeth are not aligned. the timer core rotates,

the teeth move closer together, the air gap decreases

and the magnetic field increases until the timer core

teeth and pole piece teeth are aligned (figures 6-4 and

6-5).

At this point, the magnetic field is at its strongest. As

the teeth move apart, the air gap increases and the

magnetic field decreases until the teeth begin to move

back together.

Applying the principle of electromagnetic induction

which states that a voltage will be induced in a

conductor whenever a magnetic field is moved so that

its lines of force (flux) cut across a conductor. During

the strengthening and weakening of the magnetic

field, the lines of force cut across the pick-up coil

inducing a voltage in the coil.

The principle of electromagnetic induction also states

that the polarity of the induced voltage depends on

which side of the conductor is striking the magnetic

lines first. This means that the voltage induced by a

strengthening or expanding magnetic field will be of

the opposite polarity of a voltage induced by a

weakening or collapsing magnetic field.

This signal is used to turn on and off the transistors in

the module that controls the current in the primary

circuit. With one exception, which will be covered later,

the pole piece has the same number of teeth as the

engine has cylinders. This gives the correct number of

"firing" pulses per distributor shaft rotation.

We have eliminated the contact points and breaker

cam by using a pulse generator to time the turning on

and off of the primary circuit. In place of the breaker

cam and points, transistors are used to turn the

current on and off. The wear of the rubbing block and

contact points has been eliminated as has the current

limitations of the contact points.

Current Limiting Circuit

In the past, the transistor was made to operate at a

value less than its maximum to protect it from transient

voltage and electrical current extremes. These

extremes are of short duration but of great magnitude

and can be endured by electromechani-cal devices

like switches, motors and contacts with-out permanent

damage. But for electronic devices, even a few

milliseconds (thousandths of a second) exposure to

voltage and current above its maximum capability may

cause failure. By designing the system with enough

resistance so that these extremes are within the

capabilities of the electronic devices used, these

failures were avoided. This is why no available voltage

gain was achieved.

To eliminate this problem, a current limiting circuit was

added to the HEI module to limit primary current to 5.5

amperes rather than using resistance.

This feature allows the electronic device to operate at

their maximum value. Since the HEI circuit current is

not limited by circuit resistance, the resis-tance wire

was eliminated from the system.

131-061

131-060