Summary of Contents for DCS - Series

Page 9: ...9 2 Layout Drawing Fig 2 ...

Page 26: ...26 7 Hydraulic System 1 Hydraulic Circuit Fig 13 ...

Page 28: ...28 8 Electric System 1 Electric Circuit ...

Page 29: ...29 Fig 14 ...

Page 33: ...33 4 Assembly DWG Stand Assembly Fig 15 ...

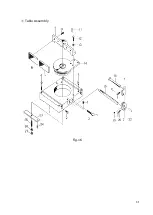

Page 35: ...35 Table Assembly Fig 16 ...

Page 37: ...37 Column Assembly Fig 17 ...

Page 39: ...39 Coolant Blade cover Assembly Fig 18 ...

Page 43: ...43 Gear Box Assembly Fig 20 ...