CONTENTS

PAGE NO.

RM3604 & 3804

AES DIAGNOSTIC FLOW CHART

1

SECTION 1

AC VOLTAGE REQUIREMENTS . . . . . . . .

3

SECTION 2

AC COMPONENTS - HEATING ELEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SECTION 3

DC VOLTAGE REQUIREMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

SECTION 4

DC COMPONENTS

4.1 Heating Element.. ........................................................................ 3

4.2 Thermostat.. ................................................................................ 3

4.3 Solenoid Valve ............................................................................ 3

4.4 Igniter.. ........................................................................................ 4

4.5 .................................................................... 4

4.6

High Voltage Cable..

Electrode ..................................................................................... 4

4.7 Relay.. ......................................................................................... 4

4.8 Door Switch ................................................................................. 5

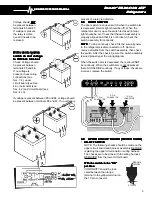

4.9 Upper Circuit Board

4.10 Circuit Board

(Switch Card). ..............................................

...............................................................................

4.1 1 Fuse ............................................................................................ 9

SECTION 5

LP GAS REQUIREMENTS . . . . . . . . . . . . . .

10

SECTION 6

LP GAS COMPONENTS

6.1 Manual Shut-Off Valve . . . .

10

6.2 Orifice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6.3 Thermocouple

10

6.4 Burner . .

10

6.5 Flue Baffle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

6.6 Flue Cap

10

6.7 Flue Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

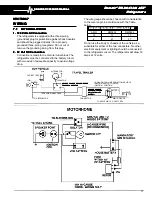

SECTION 7

WIRING

7.1 External Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

7.2 Internal Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12

SECTION 8

OTHER

8.1 Leveling ..................................................................................... 13

8.2 Ventilation ................................................................................. 13

8.3 Air Leaks ................................................................................... 13

8.4 Door Position. ............................................................................ 13

8.5 Ambient Temperature.. .............................................................. 14

8.6

Coolin

Unit.. ............................................................................. 14

8.7 Food tora

d

e ............................................................................ 14

8.8 High Humi ity ............................................................................ 14

8.9 Interior Liner Seal to Frame ....................................................... 14