10

DIAGNOSTIC SERVICE MANUAL

DIAGNOSTIC SERVICE MANUAL

DIAGNOSTIC SERVICE MANUAL

DIAGNOSTIC SERVICE MANUAL

DIAGNOSTIC SERVICE MANUAL

Dometic

Dometic

Dometic

Dometic

Dometic

®

®

®

®

®

RM3604/3804 AES

RM3604/3804 AES

RM3604/3804 AES

RM3604/3804 AES

RM3604/3804 AES

®

®

®

®

®

Refrigerators

Refrigerators

Refrigerators

Refrigerators

Refrigerators

SECTION 5

SECTION 5

SECTION 5

SECTION 5

SECTION 5

LP GAS REQ

LP GAS REQ

LP GAS REQ

LP GAS REQ

LP GAS REQUIREMENTS

UIREMENTS

UIREMENTS

UIREMENTS

UIREMENTS

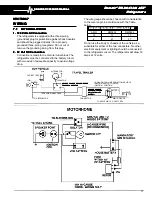

The LP gas pressure to the refrigerator should be 11

inches water column with half of all BTU's of the RV

turned on. With all other appliances off, the pressure to the

refrigerator should

not exceed 12

inches water

column. To check

the gas pressure

when the refrigerator

is operating, there is

a pressure test

housing on the solenoid.

SECTION 6

SECTION 6

SECTION 6

SECTION 6

SECTION 6

LP GAS COMPONENTS OR

LP GAS COMPONENTS OR

LP GAS COMPONENTS OR

LP GAS COMPONENTS OR

LP GAS COMPONENTS OR

MANU

MANU

MANU

MANU

MANUAL GAS SHUT

AL GAS SHUT

AL GAS SHUT

AL GAS SHUT

AL GAS SHUTOFF

OFF

OFF

OFF

OFF V

V

V

V

VAL

AL

AL

AL

ALVE

VE

VE

VE

VE

6.1

6.1

6.1

6.1

6.1

MANUAL GAS SHUTOFF VALVE

MANUAL GAS SHUTOFF VALVE

MANUAL GAS SHUTOFF VALVE

MANUAL GAS SHUTOFF VALVE

MANUAL GAS SHUTOFF VALVE

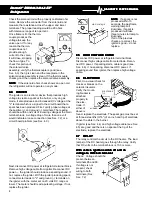

The manual gas shutoff valve is where the incoming LP

gas supply is attached. To check the shutoff valve,

remove and inspect for any obstructions. The valve must

be turned to "ON" before any gas operation can occur.

6.2

6.2

6.2

6.2

6.2

ORIFICE

ORIFICE

ORIFICE

ORIFICE

ORIFICE

The orifice is a small brass fitting that has a ruby mem-

brane that is laser beam drilled and is mounted on the gas

line just prior to the burner. The orifice is cleaned by using

an alcohol based solvent and allowing to air dry.

IMPOR

IMPOR

IMPOR

IMPOR

IMPORT

T

T

T

TANT

ANT

ANT

ANT

ANT

NEVER USE A DRILL BIT OR JET TIP CLEANER TO

CLEAN ANY ORIFICE AS THESE DEVICES WILL

DAMAGE THE FACTORY MACHINED PART AND

CREATE A POTENTIALLY DANGEROUS CONDITION.

6.3

6.3

6.3

6.3

6.3

THERMOCOUPLE

THERMOCOUPLE

THERMOCOUPLE

THERMOCOUPLE

THERMOCOUPLE

The thermocouple is a component extending above the

burner assembly so the tip is in the path of the flame. It will

produce 14 to 30 millivolts DC in normal operation. To

check the thermocouple, use a known good safety valve

and attach to the thermocouple. Next, supply flame to tip

of the thermocouple for a few moments while depressing

the safety valve. Remove the flame and release the safety

valve.

The valve should hold for at least 30 seconds. If it does

not hold the safety valve open for 30 seconds, replace

the thermocouple. If it does hold for 30 seconds or more,

the thermocouple is good — do not replace it.

NOTE

NOTE

NOTE

NOTE

NOTE: Be sure the tip on the thermocouple is clean.

6.4

6.4

6.4

6.4

6.4

BURNER

BURNER

BURNER

BURNER

BURNER

The burner is a slotted metal tube located below the flue

tube on the cooling unit. It should be level, and the slots

in the burner should be directly below the flue tube. The

burner should be cleaned periodically, at least once a

year. To clean the burner, remove from the refrigerator

and check for any foreign residue that could cause a

deflection of the gas flow or the flame. Next, soak the

burner in an alcohol based solvent and allow to air dry.

After cleaning, reinstall in the refrigerator.

6.5

6.5

6.5

6.5

6.5

FLUE BAFFLE

FLUE BAFFLE

FLUE BAFFLE

FLUE BAFFLE

FLUE BAFFLE

The flue baffle is designed to concentrate the heat (from

the gas flame) at a certain area of the flue tube. It should

be cleaned periodically, at least once a year. To clean,

remove from the flue tube and check for any damage,

then clean thoroughly. The length of the flue baffle

assembly (flue baffle and wire) for the RM3604 is 31-9/

16 inches, and for the RM3804 is 37-1/8". The flue baffle

itself for the RM3604 is 3/4 inch wide and 5-1/4 inches

long; for the RM3804, it's 3/4 inch wide and 6 inches

long. The proper baffle position for the RM3604 is 1-5/8

inches from the burner to the bottom of the baffle; for the

RM3804 the proper baffle position is 1-3/4 inches from

the burner to the bottom of the baffle.

6.6

6.6

6.6

6.6

6.6

FLUE CAP

FLUE CAP

FLUE CAP

FLUE CAP

FLUE CAP

The flue cap is located at the top of the flue tube and is

attached with a screw. It must be properly attached or

flame outage could occur.

6.7

6.7

6.7

6.7

6.7

FLUE TUBE

FLUE TUBE

FLUE TUBE

FLUE TUBE

FLUE TUBE

The flue tube is a component of the cooling

unit. It must be cleaned periodically, at

least once a year. To clean, remove flue

cap and flue baffle, then cover the burner

and clean by using a flue brush. Dometic

Part Number 0151404001. If the flue tube

becomes coated with scale or residue from

combustion of LP gas, the efficiency of gas

operation decreases.

NOTE

NOTE

NOTE

NOTE

NOTE: After cleaning be sure to reinstall

the flue baffle and flue cap.

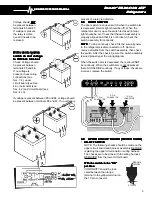

PRESSURE TEST

HOUSING

SOLENOID

Manual Gas

Shutoff Valve

3-Prong Plug

for 120V AC

IGN

LOCK

Fuse Link

3 Amp

Terminal

Block

Cover

BURNER