MAINTENANCE AND SERVICE

1. CARTRIDGE HEATER

The heat necessary for the operation of an absorption

cooling unit is supplied by an electric heater mounted in

a pocket of the boiler system.

Model RM 2552 is equipped with one electric heater for

120 volt AC.

Model RM 2553 is equipped with two electrical heaters,

one for 120 volt AC and one for 12 volt DC.

To replace the heater proceed as follows:

1.

Before working on the refrigerator make sure that 120

volt AC and optional 12 volt DC leads are disconnec-

ted. Shut off Gas valve.

2.

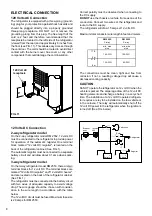

Remove the terminal block cover see FIG. 1

3.

Disconnect the heater leads.

4.

With a pair of pliers unfold the lug holding the lid of

the boiler casing and open the lid.

5.

Remove some insulation wool so that the heater is

accessible.

6.

Turn and lift the heater out of its pocket.

7.

Fit the new heater into the pocket.

8.

Connect the leads and put on the terminal block

cover.

9.

Reset the insulation and close the lid of the boiler.

2. REFRIGERATOR REMOVAL

Before working on the refrigerator, make sure the AC

voltage and DC voltage leads are disconnected. Shut off

the gas supply. Disconnect the gas supply line at the rear

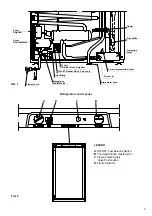

of the refrigerator, see FIG. 1. Always use a back up

wrench when loosening and tightening this connection.

Cap the gas supply line, loosen the screws anchoring

the refrigerator to the enclosure and slide the refrigerator

out of the compartment.

When replacing the refrigerator make sure that the

sealing strips are properly positioned.

Replacement is the reverse of removal. Check all con-

nections for gas leaks.

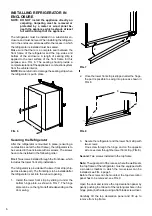

Refer to section INSTALLATION, page 4 to 8.

3. PERIODIC MAINTENANCE

To keep your Dometic refrigerator operating efficiently

and safely, periodic inspection and cleaning of several

components once or twice a year is recommended.

A.

It is important to keep the area at the back of the

refrigerator clean. Check the lower vent, upper vent

and area between these openings for any obstruc-

tions such as bird/insect nests, spider webs, etc.

Clean the coils on the back of the refrigerator. Use a

soft bristled brush to dust off the coils.

It is important to keep the refrigerator area free from

combustible material, gasoline and other flammable

vapors or liquids.

NOTE: AVOID SPRAYING WATER THROUGH

THE REFRIGERATOR VENTS WHILE WASHING

YOUR RV.

B.

Check all connections in the LP gas system (at the

back of the refrigerator) for gas leaks. The LP gas

supply must be turned on. Apply a non-corrosive

bubble solution to all LP gas connections. The ap-

pearance of bubbles indicates a leak and should be

repaired immediately by a QUALIFIED SERVICE-

MAN WHO IS FAMILIAR WITH GAS SYSTEM AND

REFRIGERATORS.

WARNING

DO NOT use a flame to check for gas leaks.

NOTE: The following maintenance is required once or

twice a year, but should only be done by a qualified

serviceman who is familiar with LP gas systems and

refrigerators.

C.

The LP gas pressure should be checked and the

main regulator readjusted if pressure is incorrect. The

correct operating pressure is 11 inches of water

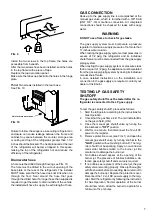

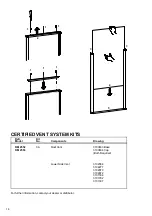

GAS EQUIPMENT ASSEMBLY

FIG. 12

BURNER JET

INLET FITTING

BURNER MOUNTING SCREW

THERMOCOUPLE

SPARK ELECTRODE

PRESSURE TEST PORT

MANUAL SHUT OFF VALVE.

Shown in open position

Use a quarter dollar or a slotted screwdriver to change position.

BURNER TUBE

NUT

11