24

Repair Manual PS-6400/PS-7300/PS-7900

yes

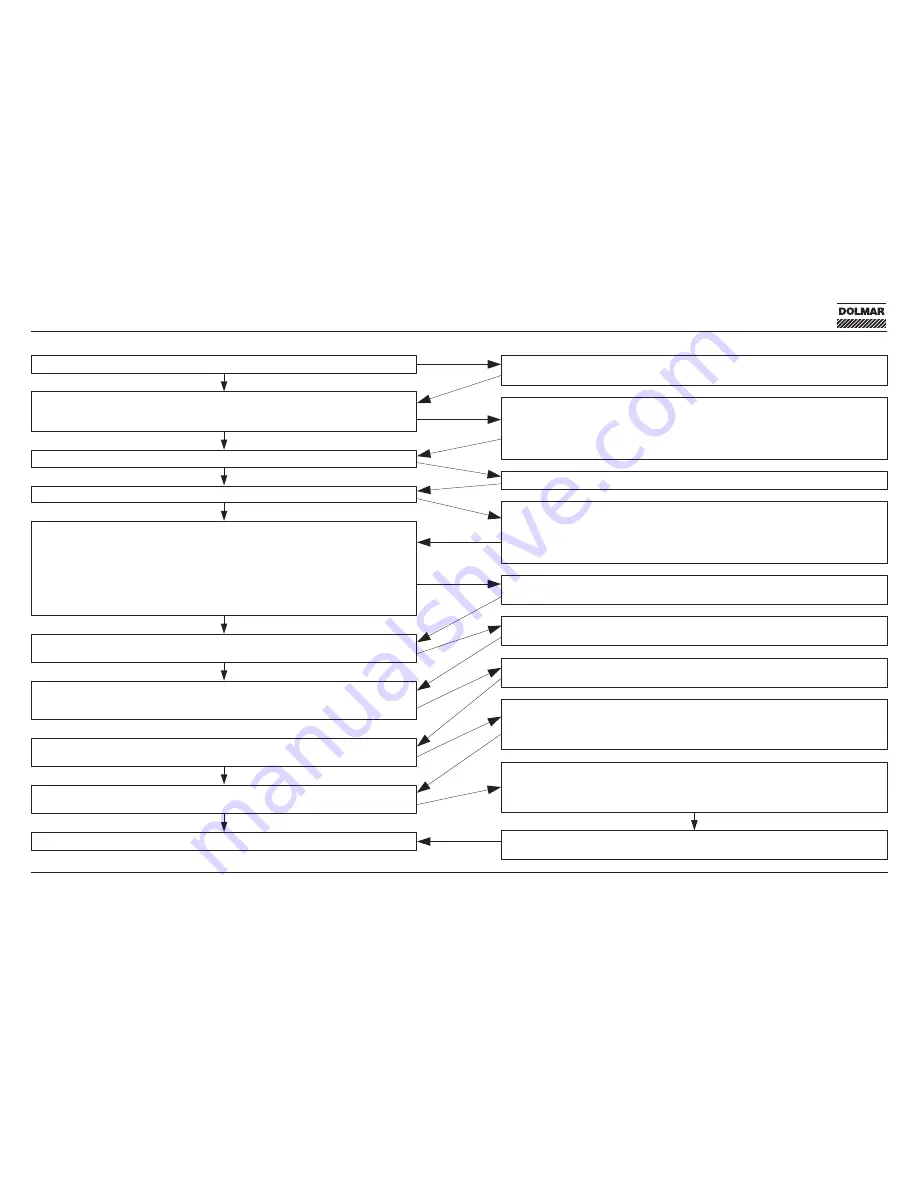

Is the ignition plug dry and correctly fastened?

Is the distance between the electrodes correct? (Should be 0.5 mm)

Is the ignition plug full of oil and sooted?

Install ignition testing lamp.

Alternatively insert combination wrench between cylinder and hood, wrench must have

metallic contact with the cylinder. Caution: Do not insert the wrench into the ignition

plug hole or hold with hand.

Push the removed ignition plug with insulated pliers against the wrench.

Caution: Do not hold the ignition plug directly against the hole. Low-speed detonation!

Pull quickly on the starting rope. Is there an ignition sparc?

Are there damages on the insulation of the high-voltage cables or the ignition plug

cable?

Remove the stop switch and set to ON. Does the switch have a low resistance? 10

Kilo Ohm or less?

Is the distance between the pole wheel and the ignition module greater than 0.3 mm?

Remove pole wheel and check. Is the pole wheel damaged? Is the spring fro

positioning damaged?

Continue with trouble shooting in fuel system (tank, fuel hose, carburetor).

Remove ignition plug. Is ignition plug damaged? has a wrong ignition plug been

used? Are the electrodes sooted?

no

yes

no

yes

no

no

no

no

no

no

no

no

yes

yes

yes

yes

yes

yes

no

no

no

Dry plug and fasten firmly on ignition plug. If needed, replace plug or spring in the

ignition plug.

Replace ignition plug. Use ONLY ignition plugs approved by DOLMAR. See operating

manual! Otherwise the ignition module might get damaged remove the causes for

sooted electrodes (bad two-tact oil), wrong mix, defect air filter). Use DOLMAR

high-performance two-tact oil.

Adjust ignition distance.

Wash ignition plug in acetone.

Do not sand blast!

If needed, replace ignition plug.

Remove cause: wrong carburetor setting, too much motor oil in fuel, frequent short

operations.

Replace ignition plug and check ignition module for corrosion, if needed replace. Has

the defect been removed.

Replace ignition cable and/or short-circuit cable. Has the defect been removed.

Replace stop switch

Has the defect been removed?

Check radial play of driving shaft and repair bearing if needed. Replace ignition

module if traces of overheating become visible. Distance pole wheel – adjust ignition

module correctly.

Replace pole wheel or spring. Wash cone seat at drive shaft and pole wheel before

installation with acetone or alcohol to remove any grease. Heed the torque of the

fastening nut! Has the defect been removed?

Replace ignition module. Has the defect been removed.?

no

07

I G N I T I O N S Y S T E M

Inspecting the ignition system