User Information

Ringlock

General

77

999817902 - 10/2022

Additional Safety Guidelines

Scaffolding Operations

Please note that this guidance is offered to you as a

minimum requirement for scaffolder's to work safely. If

you work on a site with more stringent Company proce-

dures (i.e. continuous attachment policy, inertial reels,

etc.) then this will take precedence.

▪

It is recommended that scaffolders work in accord-

ance with TG4 (latest edition), at all times when

erecting dismantling or altering scaffolding. Working

at height PPE should be worn as dictated by proce-

dure and/or site requirements. Your fall arrest equip-

ment should be thoroughly checked each shift before

starting work. Report any suspected defects to your

Company management.

▪

Measures to prevent falls should always be consid-

ered before resorting to fall arrest equipment. Scaf-

folders should therefore install as a minimum, a sin-

gle guardrail to each lift at all locations in accordance

with TG4 (latest edition). Advanced guardrail sys-

tems, scaffolder steps or other propriety equipment

may be employed to erect the edge protection.

▪

Additional methods may be employed including

safety nets, inertia reel blocks, and horizontal line

systems. These should be considered when plan-

ning your job and if necessary be included in your

Risk Assessment. Specialist training or guidance will

be required to use this proprietary equipment.

▪

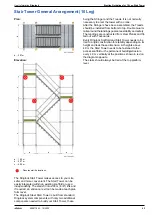

Scaffolders must erect the full width of the platform

by using the appropriate number of Planks.

▪

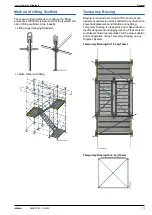

It is recommended the scaffolder clips to a suitable

anchorage point and remain attached at all times

when at risk of a fall (refer to 'Safety Harness Con-

nection Points' for suitable/appropriate harness loca-

tions.) This will include when:

- Working outside the protected area (i.e. decked

platform and single guardrail).

- Raising and lowering scaffolding compo-

nents(e.g. 'handballing').

- Fixing/dismantling scaffolding components.

- Moving the working platform (e.g. when raising

or lowering steel planks).

▪

Ladders should be fitted as early as possible during

erection and removed as late as possible during dis-

mantling to eliminate the need to climb the scaffold

structure. Refer to section 'Use of Ladders'.

▪

A suitable rescue procedure should be put in place

to urgently retrieve an individual in the event of an

arrested fall. This should be part of your Risk

Assessment and understood by all involved before

starting any job.

▪

The erection of Ringlock system scaffolding is a

skilled task and must only be carried out by trained

personnel. By the very nature of the work, the haz-

ards are severe and accidents frequently result in

serious injuries or fatalities.

▪

Before commencing work, check that all necessary

clearances or permits have been obtained and

always check the Risk Assessment and sign to sig-

nify your understanding.

▪

It is recommended that you check your scaffold tools

each day before work, to ensure that all parts are in

good condition, if you discover or suspect any

defects, report them immediately to your Company

management. Do not use faulty equipment.

▪

Be aware, and make your workmates aware of any

potential hazards near your place of work, i.e. nox-

ious fumes, acids, electrical plant, overhead conduc-

tors, excessive heat, working machinery etc.

▪

Obtain and use any required safety equipment, e.g.

inertia reel blocks, running lines respirator, goggles,

etc., and always wear a safety helmet, safety boots,

overalls, gloves, eye protection and a safety har-

ness.

▪

Where there is a possibility of other persons passing

through or near the work zone, ensure that suitable

barriers or signs are erected to warn and exclude

them from the danger area.

▪

During scaffold erection, ensure that you and all

other members of the scaffolding team, do the fol-

lowing:

- Use gin wheel and rope for raising and lowering

scaffolding components, DO NOT throw scaf-

folding components up or down. (Refer to Safety

Guidelines 'Gin Wheels and Ropes'.)

- When at height ensure that at all times you take

the necessary precautions to ensure a safe

method of work and prevent a fall.

- Erect advanced guardrails wherever possible

and as soon as practicable.

- Ensure that all members of the scaffolding gang

have sufficient experience of erecting 'Advanced'

or 'Special' structures. Do not take unnecessary

risks.

- Check all components are serviceable before

use. Reject and report to your Company man-

agement any defective components.

▪

Always ensure that the foundations or structure from

which a scaffold is to be built are adequate:

- Use Base Jacks and timber sole boards under

every standard. On soft ground or where there is

any likelihood of surface penetration ensure an

adequate base is provided for each standard.

- If the scaffold is to be erected on a roof or over a

basement or upper floor, check with the Client,

that the foundation is suitable or if back propping

or shoring is required.

- Inform your Company management if excava-

tions are taking place in the immediate vicinity of

the scaffold base.

- Ensure that the scaffold is erected in accordance

with the Ringlock Technical manual, Engineering

Solutions (if applicable) or a supplied design-

drawing. If the information is not received or if

you are in any doubt, contact your Company

management.

- Ensure that the scaffold is adequately tied to the

building or structure in accordance with the tie

patterns in the Technical Manual. During erec-

tion, fit ties progressively as soon as the speci-

fied height is reached. When dismantling each

tie should be removed as late as possible and if

necessary fit alternative means to maintain sta-

bility.

- Ensure that all guardrails and toeboards are fit-

ted to all edges of platforms (including return