4

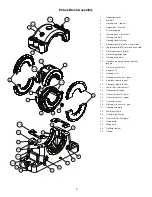

5. INSTALLATION OF UPPER LINER

Apply oil to faces of thrust collars next to liner and to shaft in

journal area and to journal surface of upper liner.

Locate upper liner in place on lower liner, taking care to align dowel

pins and match marks. (The upper liner has a recess(es) for the oil

ring(s)). Make sure oil ring(s) rotate freely.

Install and tighten liner cap screws to torque listed in Table 3.

Table 3 - Torque Values for Liner Cap Screws (in.-lbs.) ft.-lbs.

Shaft

Size

(inches)

2-15/16

3-7/16

3-15/16

4-7/16

4-15/16

5-7/16

Liner

Cap

Screw

(58) 5

(58) 5

(58) 5

(58) 5

(114) 10 (114) 10

Shaft

Size

(inches)

6

7

8

9

10

12

14

Liner

Cap

Screw

(114) 10 (114) 10 (510) 43 (510) 43

(1050)

88

(1050)

88

(1050)

88

Collars should run parallel to thrust faces of liner within

.001 in

.

Tighten housing base to pedestal. See Table 4 for torque.

MATCH

MARKS

CHECK LINER THRUST FACE &

COLLAR CLEARANCE

Recheck clearance

(0.015 to 0.035 in. total)

and parallelism

(0.002 in max.)

of thrust collars to liner faces.

Table 4 - Torque Value for Housing Hardware (in.-lbs.) ft.-lbs.

Housing

Size

3

4

5

6

8

10

Housing

to

Pedestal

Bolts

(2000)

167

(3600)

300

(4600)

383

(8400)

700

(11500)

958

(15000)

1250

Housing

to

Cap Bolts

(1560)

130

(2280)

190

(2280)

190

(2280)

190

(3240)

270

(3240)

270

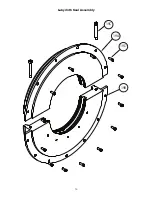

6. INSTALLATION OF HOUSING CAP

Position shims on each side of housing. Put a short strip of

Plastigage (3 inches) on liner spherical ribs at top of each rib of

liner and near the middle of spherical ribs.

PLASTIGAGE

NOTE: New housing shims are required with replacement

liners.

CAREFULLY set housing cap in place.

NOTE: Align dowel pin and dowel pin hole in housing halves

before lowering cap onto base.

Tighten housing cap bolts to torque specified in Table 4.

Remove cap bolts and housing cap.