15

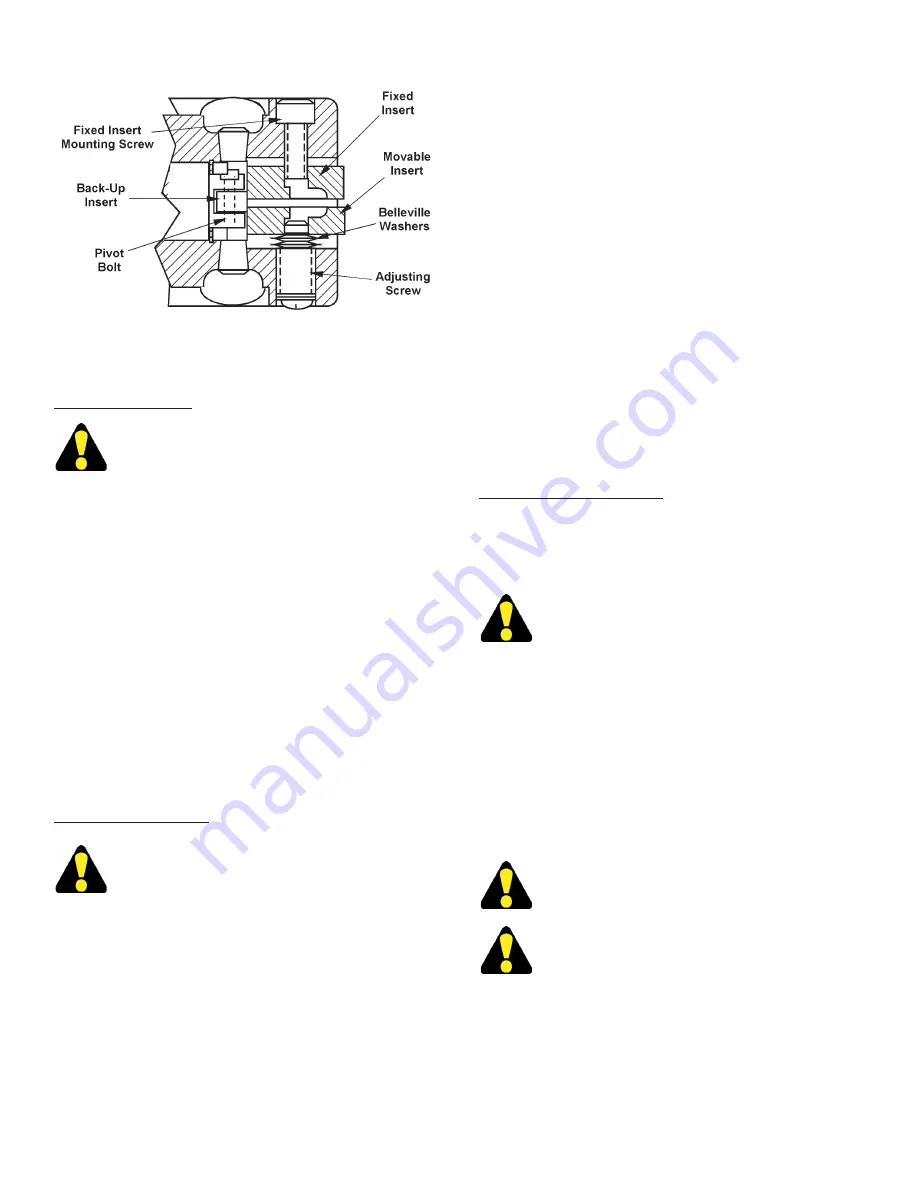

Saw Guide Insert Components.

2.

This applies to both upper and lower saw guides.

Saw Band Removal

Always use extreme care when handling saw

bands. Wear gloves.

1.

Before removing the saw band, set the machine to

the following conditions:

(a)

Hydraulics are on;

(b)

Band drive motor is off;

(c)

Coolant is completely

shut off;

(d)

Saw head is vertical and completely

retracted;

(e)

Position the post at the midrange

height.

2.

Move the

Band Tenson

selector switch to

"release". Then:

(a)

Open the upper bandwheel

door;

(b)

Loosen the band brush bracket screw

and move the brush aside;

(c)

Loosen the saw

guide insert adjustment screws two (2) full turns

counterclockwse

;

(d)

Carefully remove the old,

worn or broken saw band from between the saw

guide inserts and both bandwheels;

(e)

Carefully

work the saw band out from the column guard and

dispose the saw band immediately.

Saw Band Installaton

Always use extreme care when handling saw

bands. DO NOT attempt to change saw bands

whle the band drve motor s runnng.

1.

Carefully follow all

"Saw Band Removal"

procedures.

Then:

(a)

Use the

Flushng Hose

to clean areas

around the saw guides and inserts, plus the drive

and idler bandwheels;

(b)

Wiper with clean rag.

2.

Maneuver the saw band into the column guard.

Then:

(a)

Carefully position the saw band around

the drive and idler bandwheels with the saw band's

back edge resting against each bandwheel's rear

flange;

(b)

Move the

Band Tenson

selector switch

to "tension" to apply just enough tension to hold the

saw band in position, then move the selector to the

center position to "hold".

3.

Slip the saw band between the saw guide inserts

by twisting it 90° using the supplied saw band twist

tool so the blade teeth are facing the front of the

machine and pointing downward. Then:

(a)

Turn

the adjustment screw two (2) full turns

clockwse

to provide correct pressure against the saw band;

(b)

Remove the protective Saw Cap from the saw

band;

(c)

Close the the upper bandwheel door;

(d)

Move the

Band Tenson

selector switch to "tension"

to apply full tension to the saw band.

4.

Turn the

Band

selector switch to "run" and operate

at a very low speed to check for proper band tracking

against the each bandwheel rear flange.

Band Tenson Adjustment

1.

Located on the rear side of the column and accessed

from the left side, band tension is hydraulically

applied and maintained.

DO NOT operate the band drve motor unless

band tenson selector s n the "tenson"

poston.

POST ADJUSTMENT

1.

Post and upper saw guide height is regulated by

the

Post

selector switch on the control panel.

2.

Sawing results will generally be more satisfactory if

the post and upper saw guide are kept as close as

possible to the material being cut. Doing so helps

reduce saw band vibration and contributes to more

accurate sawing.

The post can be lowered only when the saw

head s fully retracted.

When the saw head has been tlted, make sure

the post and saw gude wll clear the materal

and/or the vse jaws.

SAW BAND PREPARATION (Continued....)

Summary of Contents for TF-2525

Page 5: ... MACHINE DIMENSIONS FLOOR PLAN INCHES 03 MILLIMETERS 1 mm ...

Page 6: ... MACHINE DIMENSIONS Continued FRONT VIEW ...

Page 8: ... MACHINE FEATURES FRONT VIEW REAR VIEW ...

Page 9: ... MACHINE FEATURES Continued SIDE VIEW ...

Page 10: ... MACHINE FEATURES Continued HEAD ASSEMBLY ...

Page 25: ...21 LUBRICATION Next 2 Pages ...

Page 27: ...23 LUBRICATION DIAGRAM LOWER HEAD REAR VIEW POWER UNIT REAR VIEW ...