2

IMMEDIATE HAZARDS

WHICH WILL RESULT IN

SEVERE PERSONAL INJURY

HOPPER GUARD

LISTED BELOW IS THE DEFINITION OF THE HAZARD

LEVEL USED ON THE SAFETY STICKERS.

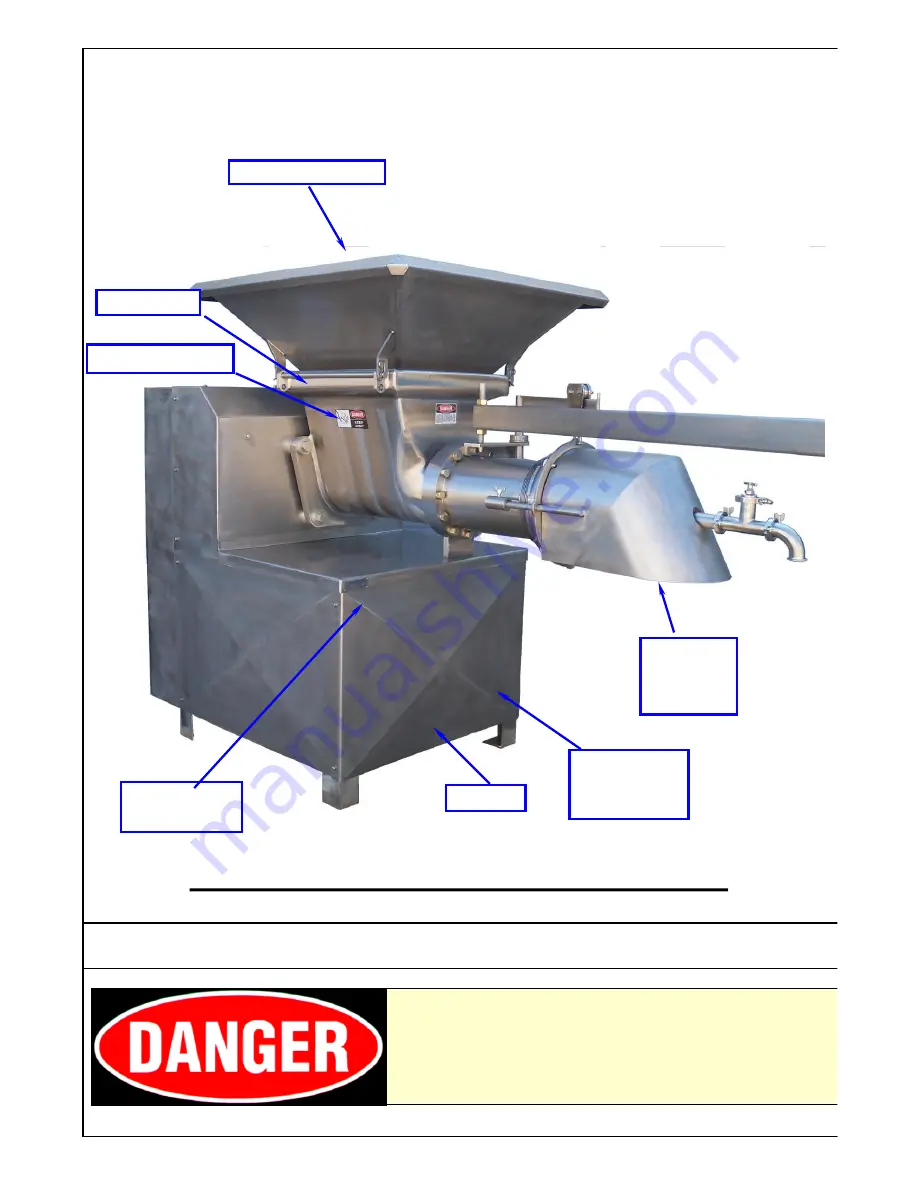

TYPICAL DIXIE 16-10 GRINDER UNIT

FRAME

MOTOR

COVER

PANELS

SERIAL

NUMBER

HOPPER

SAFETY TAG

ORIFICE

PLATE

GUARD