16

Maintenance

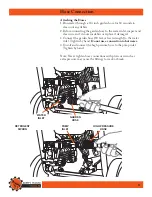

BEFORE PERFORMING ANY MAINTENANCE

PROCEDURE STOP THE ENGINE, WAIT FIVE (5)

MINUTES TO ALLOW ALL PARTS TO COOL.

Turn the engine switch to the OFF position.

Regular maintenance is the way to ensure the best performance

and long life of your machine. Please refer to this manual and the

engine manufacturer’s owner’s manual for maintenance procedures.

!

WARNING

Maintenance

Before

Monthly/

Every 6 Mo./

Annually/

Procedure

Each Use

20 Hours

50 Hours

100 Hours

Clean Exterior Surfaces

X

X

X

X

Remove Accumulated Debris

X

X

X

X

Check Engine Oil Level

X

X

X

X

Change Engine Oil*

X

X

X

Check /Clean Water Inlet Screen

X

X

X

X

Check High Pressure Hose

X

X

X

X

Check Detergent Siphoning Hose/Filter

X

X

X

X

Check Spray Gun & Hose Connections

X

X

X

X

Check/Clean Air Filter**

X

X

Check Muffler and Spark Arrestor

X

X

Clean/Replace Spark Plug

X

Maintenance Checklist

* Change engine oil after the first 5 hours of operation as break-in period

** Change/clean air filter more frequently if in dusty environment

• The pump is pre-lubricated and factory sealed requiring no additional

maintenance for the life of the pump.

• Keep area around muffler free from any combustible debris.

• Air slots and openings on the power washer must be clean and unobstructed.

• Power washer parts should be clean to reduce overheating or ignition of debris.

Summary of Contents for 101087

Page 22: ...22 Notes...

Page 23: ...23 Notes...