17

To prevent the USB cable

from coming off

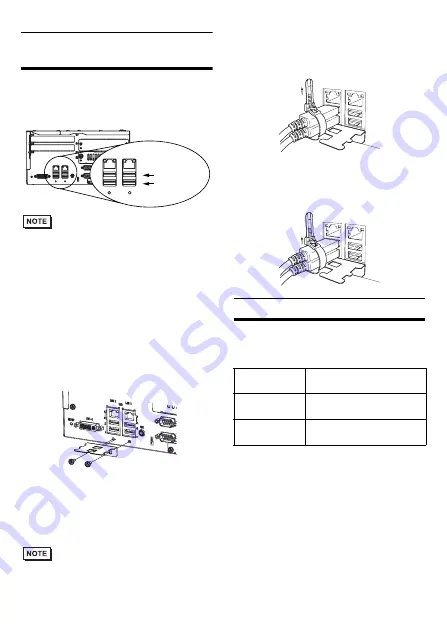

Attaching the USB Cable Clamp

(1) Place the PL unit face-down on a flat sur-

face as shown below. Your PL unit has

four USB connectors.

• When using two or more USB ports, be sure

to first connect one USB cable to the lower

USB connector, and then connect the sec-

ond USB cable to the upper USB connector.

• When using only one of the USB ports, be

sure to use the lower USB connector. This

allows you to securely clamp the USB

cable in the cable clamp.

• The USB cable clamp is not compatible

with the USB connector on the front face.

(2) Fix the USB holder with two screws.

The torque required to tighten these

screws is 0.5 to 0.6 N•m.

(3) As the figure shows, pass the USB Cable

Clamp’s band around the depressed sur-

face of the holder, twist the USB Cable

Clamp’s band around the USB cable, pull

the band in the direction of the arrow, and

then fasten the band using the clamp.

• Be sure the clamp is securely holding the

USB cable’s plug and collar.

• Be sure the clamp is positioned as shown

below, with the clamp pointing upwards - not to

the side. This is to keep the clamp from interfer-

ing with nearby connectors and their cables.

Removing the USB Cable Clamp

(1) To remove the clamp from the USB cables,

push down on the clamp strap’s clip to

release it while pulling up on the clamp.

UL/c-UL Approval

The following units are UL/c-UL listed

products:

(UL File No.E220851)

These products conform to the following

standards:

UL508

Industrial Control Equipment

CSA-C22.2 No.142-M1987

(c-UL Approval)

Process Control Equipment

<Cautions>

Be aware of the following items when

building the PL into an end-use product:

1

2

4

3

USB

LAN1

LAN2

1

2

4

3

USB

LAN1

LAN2

SPK

DV1-I

RESET

Lower USB

Interface

Upper USB

Interface

Product

Model No.

UL/c-UL

Registration Model No.

APL3900-TA

3582302-0

Front Module:3620003-03

APL3900-TD

3582302-11

Front Module:3620003-03