REF#

PARTS DESCRIPTION

REQ

PART #

1

1/8" BRASS COUPLER

1

9996

2

CUTTERSHAFT BEARING

2

10-0006

3

OIL BATH REPLACEMENT BEARING

2

10-1067

4

3/8 LOCK WASHER

7

11-0005

5

3/8 FLAT WASHER

25

11-0009

6

1/2 LOCK WASHER

24

11-0011

7

1/2 H.S. LOCK WASHER

8

11-0036

8

1/2 SAE FLAT WASHER GR 8

9

11-0042

9

KNIFE MOUNTING BOLT

56

11-0506

10

1/2 X 2 NC PLOW BOLT

8

11-0515

11

1/2 X 1-3/4 NC PLOW BOLT

3

11-0530

12

3/8 X 1 NC HEX CAPSCREW

7

11-0532

13

3/8 X 1-1/4 NC HEX CAPSCREW

18

11-0533

14

1/2 X 1-1/2 NC HEX CAPSCREW

5

11-0534

15

1/2 X 1-3/4 NC HEX CAPSCREW

8

11-0535

16

1/2 X 2 H.S. NF HEX CAPSCREW

8

11-0633

17

3/8 X 1 H.S. NC SKT HEAD

12

11-0752

18

1/2-13 X 1-1/2 GR 8 HEX CAPSCREW

4

11-0972

19

3/8 NC HEX NUT

25

11-1001

20

3/4 - 6 ACME HEX NUT

2

11-1012

21

1/2 NC HEX NUT

24

11-1016

22

7/16 NYLOCK JAM NUT

56

11-1146

23

CLEVIS

56

11-1501

24

1/2-13 X 1-1/8 GR 8 HEX CAPSCREW

5

11-2154

25

102" FLAP

1

18-0012

REF#

PARTS DESCRIPTION

REQ

PART #

26

GREASE ZERK HOSE

1

21-0002

27

1/8" GREASE ZERK

2

23-0003

28

102" SKID LOADER FLAIL BONNET

1

25-0199

29

GROUND ROLLER MOUNT PLATE

1

31-0755

30

GROUND ROLLER BOLT PLATE INTERIM

2

31-0761

31

LOCK PLATE

4

41-0003

32

ADJUSTMENT ROD RIGHT

1

41-0005

33

ADJUSTMENT ROD LEFT

1

41-0006

34

102" TRASH GUARD

1

41-0031

35

CUTTERSHAFT GUARD

1

41-0097

36

102" FLAP BAR

1

41-0127

37

ADJUSTMENT BRKT W-O TAPPED HOLES

2

41-1774

38

RIGHT SKID SHOE

1

42-0010

39

LEFT SKID SHOE

1

42-0013

40

BEARING GUARD

4

46-0018

41

102" GROUND ROLLER

1

46-0052

42

****CUTTER SHAFTS COMPLETE****

102" CUTTER SHAFT, SMOOTH CUT KNIVES Opt.

46-1014

102" CUTTER SHAFT, 3/16" HD KNIVES

1

46-1016

43

****FLAIL KNIVES****

SMOOTH CUT FLAIL KNIFE

56

22-1006

3/16" HD FLAIL KNIFE

112

22-1016

44

BLADE KITS

Includes 11-0506, 11-1146, & 22-1016 (HD)

1

44-0261

Includes 11-0506, 11-1146, & 22-1006 (smooth)

1

44-0244

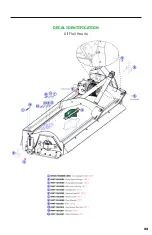

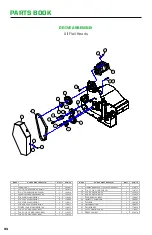

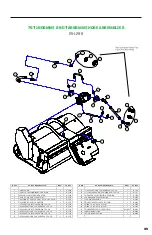

PARTS BOOK

102”(2591MM) CUTTER ASSEMBLY

25-1603

32