6. Replace punch and reassemble tool by reversing steps 2-5

above.

BE SURE TO THOROUGHLY CLEAN AND LIGHTLY OIL ALL

LOCATING SURFACES BEFORE REASSEMBLY TO PREVENT

DAMAGE TO TOOL. ALSO MAKE CERTAIN THAT STRIPPER IS

SECURELY LOCKED IN POSITION AND PUNCH IS PROPERLY

SEATED BEFORE FINALLY TIGHTENING THE PUNCH

RETAINING SET SCREW.

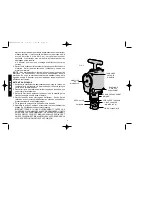

Removing Die

1. Remove 2 die screws located an an angle at bottom rear of shoe

and remove die (Figure 1).

2. If sharpening of die is required, sharpen on a surface grinder by

removing material from only the top surface of the die. Grinding by

a qualified machine shop is preferred.

CAUTION: Remember

that the total amount of metal removed from both the punch and

the die cannot exceed 3/32".

3. Clean die and shoe surface thoroughly.

4. Insert die in tool.

5. Replace screws and tighten securely.

Maintenance

Nibblers should be cleaned, inspected, and lubricated at certified

D

E

WALT service centers every month with heavy usage, every two or

three months with light usage.

Inspect carbon motor brushes frequently by unplugging tool,

removing the brush inspection caps, and withdrawing the brush and

spring assembly. Replace the assembly when the brushes are worn

down to the line closest to the spring, or when spring exerts

insufficient pressure to hold brush against commutator. Keep brushes

clean and sliding freely in their guides.

Saturate the felt oiler with SAE 10W or 20W motor oil once very day

of operation in normal use.

3

English

FIG. 1

CRANK DOWN

SLOT

OIL FILLER

PLUG

OIL FLOW

CONTROL KNOB

STRIPPER

SHOE

STRIPPER MOUNTING

SCREWS (2)

DIE

DIE SCREWS (2)

CLEARANCE HOLE

FELT OILER

DW899/384346 IM 5/2/02 1:44 PM Page 3