29

EnGLIsh

Soft Start Feature

The soft start feature allows a slow speed build-up to avoid an

initial jerk when starting. This feature is particularly useful when

working in confined spaces.

Electronic Variable Speed Control

The electronic variable speed control offers added tool control

and enables the tool to be used at optimum conditions to suit

the accessory and material.

Auto-balance Feature

The auto balance feature continuously adjusts the balance to

reduce the vibration of the machine when it is running. This

improves user comfort during the operation and is particularly

useful when using the machine for long periods of time.

Clutch

The torque limiting clutch reduces the maximum torque

reaction transmitted to the operator in case of jamming of a

disc. This feature also prevents the gearing and electric motor

from stalling. The torque limiting clutch has been factory-set

and cannot be adjusted.

No-volt Release Switch

The on/off switch has a no-volt release function: should the

power be shut off for some reason, the switch has to be

deliberately reactivated.

Overload Protection

The power supply to the motor will be reduced incase of motor

overload. The power will return to normal once the tool has

cooled down to suitable operating temperature.

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from

power source before making any adjustments or

removing/installing attachments or accessories.

Before reconnecting the tool, depress and release

the trigger switch to ensure that the tool is off.

An

accidental start-up can cause injury.

Attaching the Side Handle (Fig. E)

WARNING:

Before using the tool, check that the handle is

tightened securely.

WARNING:

The side handle should always be used to

maintain control of the tool at all times.

Screw the side handle

4

tightly into one of the holes

18

on

either side of the gear case.

Mounting and Removing the Guard (Fig. B)

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from

power source before making any adjustments or

removing/installing attachments or accessories.

Before reconnecting the tool, depress and release

the trigger switch to ensure that the tool is off.

An

accidental start-up can cause injury.

1. Remove the screw

11

.

2. Place the angle grinder on a table, spindle up.

3. Release the clamping lock

8

and hold the guard

3

over the

tool as shown.

4. Align the lugs

9

with the notches

10

.

5. Press the guard down and rotate it to the required position.

6. Replace the screw

11

.

7. If required, increase the clamping force by tightening the

screw

11

.

8. Tighten the clamping lock.

9. To remove the guard, release the clamping lock.

WARNING:

Never use the tool without the guard in place.

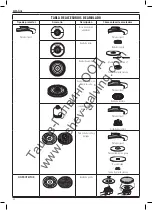

nOTE:

Please refer to the

Grinding Accessory Chart

at the end

of this section to show other accessories that can be used with

these grinders.

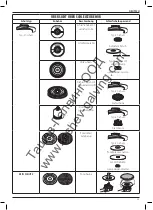

Fitting and Removing a Grinding Disc

(Fig. C, D)

WARNING:

Do not use a damaged disc.

1. Place the tool on a table, guard up.

2. Fit the inner flange

12

correctly onto the spindle

13

(Fig. C).

3. Place the disc

14

on the flange

12

. When fitting a disc

with a raised centre, make sure that the raised centre

15

is

facing the flange

12

.

4. Screw the outer flange

17

onto the spindle

13

(Fig. D).

The ring on the flange

17

must face towards the disc when

fitting a grinding disc.

5. Press the spindle lock

2

and rotate the spindle

13

until it

locks in position.

6. Tighten the flange

17

with the two-pin spanner supplied.

7. Release the spindle lock.

8. To remove the disc, loosen the flange

17

with the two-

pin spanner.

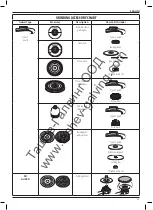

Fitting and Removing a Backing

Pad/Sanding Sheet (Fig. A, D)

1. Place the tool on a table, guard up.

2. Remove the backing flange

12

.

3. Place the rubber backing pad correctly onto the spindle

13

.

4. Place the sanding sheet on the rubber backing pad.

5. Screw the threaded clamp nut

17

onto the spindle. The

ring on the threaded clamp nut

17

must face towards the

rubber backing pad.

6. Press the spindle lock button

2

and rotate the spindle

13

until it locks in position.

7. Tighten the threaded clamp nut

17

with the two-

pin spanner.

8. Release the spindle lock

Та

ше

в

-

Га

лв

ин

г

ОО

Д

www.tashev-galving.com