PAGE

7

Do not store the tool in cold weather. Frost

or ice can form on the operating valves or

mechanisms and the tool may not operate

correctly.

In cold weather operation (near or below

freezing), DO NOT USE a permanent

antifreeze such as ethylene glycol for a

cold weather lubricant. This type of

anitfreeze will damage o-rings and seals

of the tool.

NOTE

Proper lubrication is the owner's re-

sponsibility.

Failure to lubricate the tool

properly will dramatically shorten the life

of the tool and void your warranty.

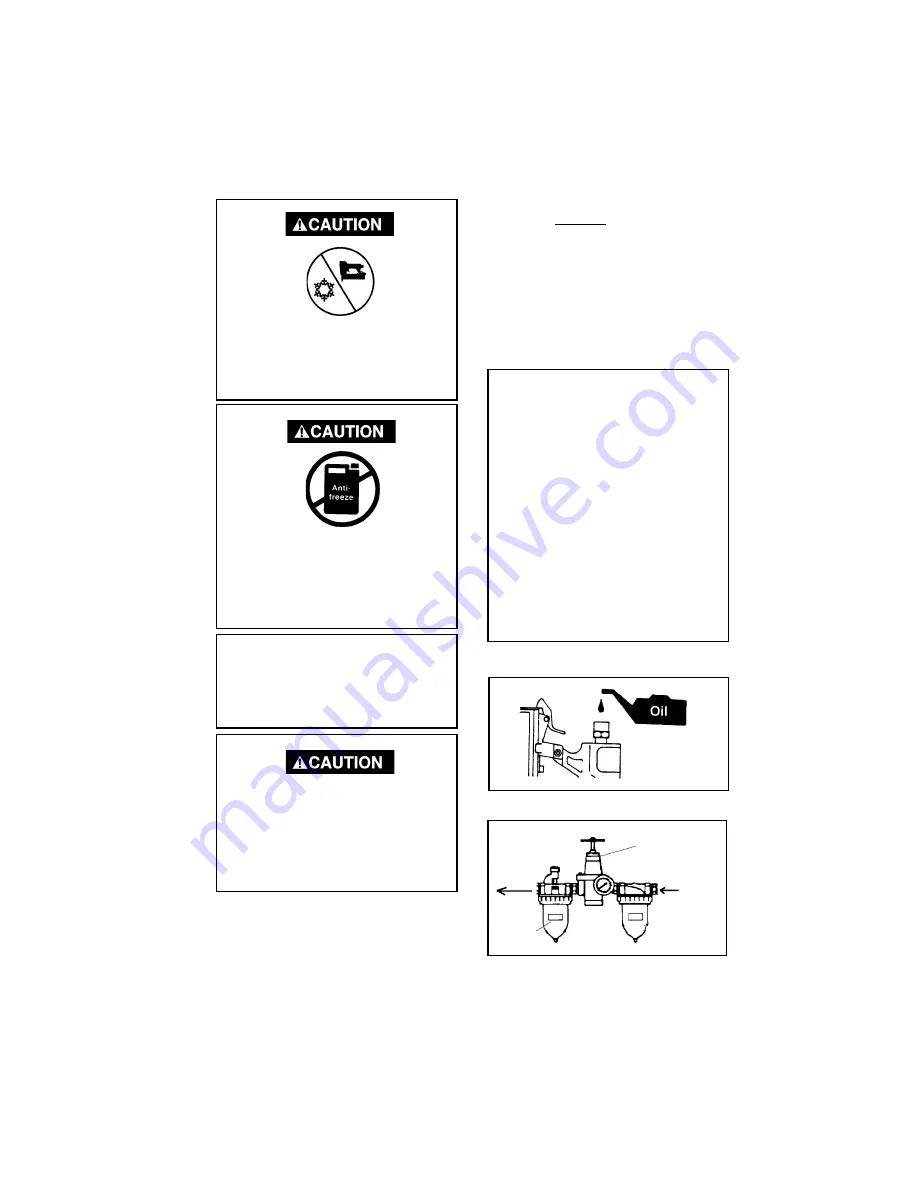

1.

Disconnect the air supply from the tool

before manually lubricating.

Your tool requires lubrication before

you use it for the first time and before

and after each additional use.

If an

Oiler

is used, manual lubrication through the air

inlet is not required on a daily basis.

Lubrication prevents wear and prevents

rust from forming.

LUBRICATION AND MAINTENANCE

2.

Turn the tool so the air inlet is facing up

and put

one drop

of DeVilbiss AC230 Air

Tool Oil, high speed spindle oil, such as

Unocal RX22, or 3-in-1 oil into the air

inlet. DO NOT USE detergent oil or addi-

tives. Operate the tool briefly after add-

ing oil.

(See Figure 1)

DO NOT OVER LUBRICATE AIR TOOL.

3.

Wipe off excessive oil at the exhaust.

NOTE

Many air tool users find it convenient to use

an

Oiler

to help provide oil circulation

through tool. An

Oiler

also increases the

efficiency and useful life of the tool. An oiler

is recommended for tools that receive heavy

or constant use. Check oil level in the oiler

daily.

(See Figure 2)

Many air tool users find it convenient to use

a

Filter

to remove liquid and solid impuri-

ties which can rust or "gum up" internal

parts of the tool. A

Filter

also increases the

efficiency and useful life of the tool. Drain

water from the filter periodically.

(See

Figure 3)

Regulator

Oiler

Figure 1

Air Flow

Figure 2