4

4

Product Guide

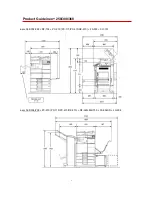

ineo+ 258/C308/C368

Product Guide ineo+ 258/308/368

Product basics

MODEL DEVELOPMENT

CODE

Zeus S Z

Zeus S X

Zeus S 0

Zeus S 1

Zeus S 2

Zeus S 2.5

MODEL NAME

ineo+

658

ineo+

558

ineo+

458

ineo+

368

ineo+

308

ineo+

258

SUCCESSOR MODEL FOR

ineo+

654e

ineo+

554e

ineo+

454e

ineo+

364e

ineo+

284e

ineo+

224e

ALSO AVAILABLE AS

KM bizhub

C658

KM bizhub

C558

KM bizhub

C458

KM bizhub

C368

KM bizhub

C308

KM bizhub

C258

Olivetti

d-Color

Olivetti

d-Color

Olivetti

d-Color

Olivetti

d-Color

MF364

Olivetti

d-Color

MF304

Olivetti

d-Color

MF254

ESTIMATED SALES

START

08/2016

09/2015

01/2016

INFOSOURCE SEGMENT

Col IV

Col IV

Col III

AVERAGE MONTHLY

PAGE VOLUMES

(exp. colour ratio: 30%)

25k

16k

13k

MAX MONTHLY PAGE

VOLUMES

(KMI specified)

125k

100k

80k

(If the maximum volume is reached within a period of one year, then a maintenance cycle must

be performed!)

MACHINE LIFE

1500k or 5

years

1000k or 5

years

800k or 5

years

MCBF (Mean

Copies Between

Failure)

Total

Colour

Mono

63,5k

53,1k

69,3k

55,1k

46,0k

60,1k

48,0k

40,2k

52,4k

MCBJ (Mean Copies

Between Jam)

10k with standard paper

STANDARD COPY MODE

(MONO & COLOUR)

4 pages/

job

3 pages/

job

3 pages/

job

STANDARD ORIGINAL

DENSITY

5 % Mono & Colour

SAFETY & ENVIRONMENT

Available on CSES

PLEASE NOTICE

Standard paper weight for systems is 80 g/m

2

for monochrome machines. Since using these standards result in optimum system

performance, all specifications on performance, reliability, maintenance and replacement based on those standard papers. Using thick

papers, labels, transfer and polyester films continuously can increase the wear and tear on replacement parts and consumables

– meaning

your servicing costs will go up. Use the bypass or the lower tray from the paper feed unit when working with materials having such

characteristics as polyester films, textile transfer films and labels. Otherwise, you may be faced with double feeding or a higher number of

feeding jams. If possible use subtray when working with materials having such characteristics as polyester films, textile transfer films and

labels. Rollermarks on the copy or print may appear or increased jams can occur. Standard paper weights yield the best possible copy and

print results. Using higher grammatures may influence the quality of the output. Using standard paper weights also guarantees that double

sided copies and prints are made reliably. Different characters of films as well as thick, thin and coated papers may increase the jam rate for

double sided copies and prints.