Instruction Manual

for

DEUBLIN

Bore-Mounted

Two-Channel Rotating Unions

Model/Series:

1112-240-001

Number:

Release: 275 V

Page 9 of 11

DEUBLIN Company • 2050 Norman Drive • Waukegan IL 60085-6747 USA • +1-847-689-8600 •

+1-847-689-8690 •

Preventing Premature Seal Failure

During tool change, most machining centers supply air flow to keep the taper of the drawbar mechanism clean.

When this air flow is supplied through the union and the new tool is “dead-ended” (i.e., not designed for

through-spindle coolant), air pressure may become trapped between the new tool and the check valve in the

air line, thereby keeping the Pop-Off™ seal faces closed. Subsequent spindle rotation without coolant will

cause overheating and premature failure of the seals. To avoid this, trapped air must be vented. Consult

Deublin for assistance on how best to do this in your application.

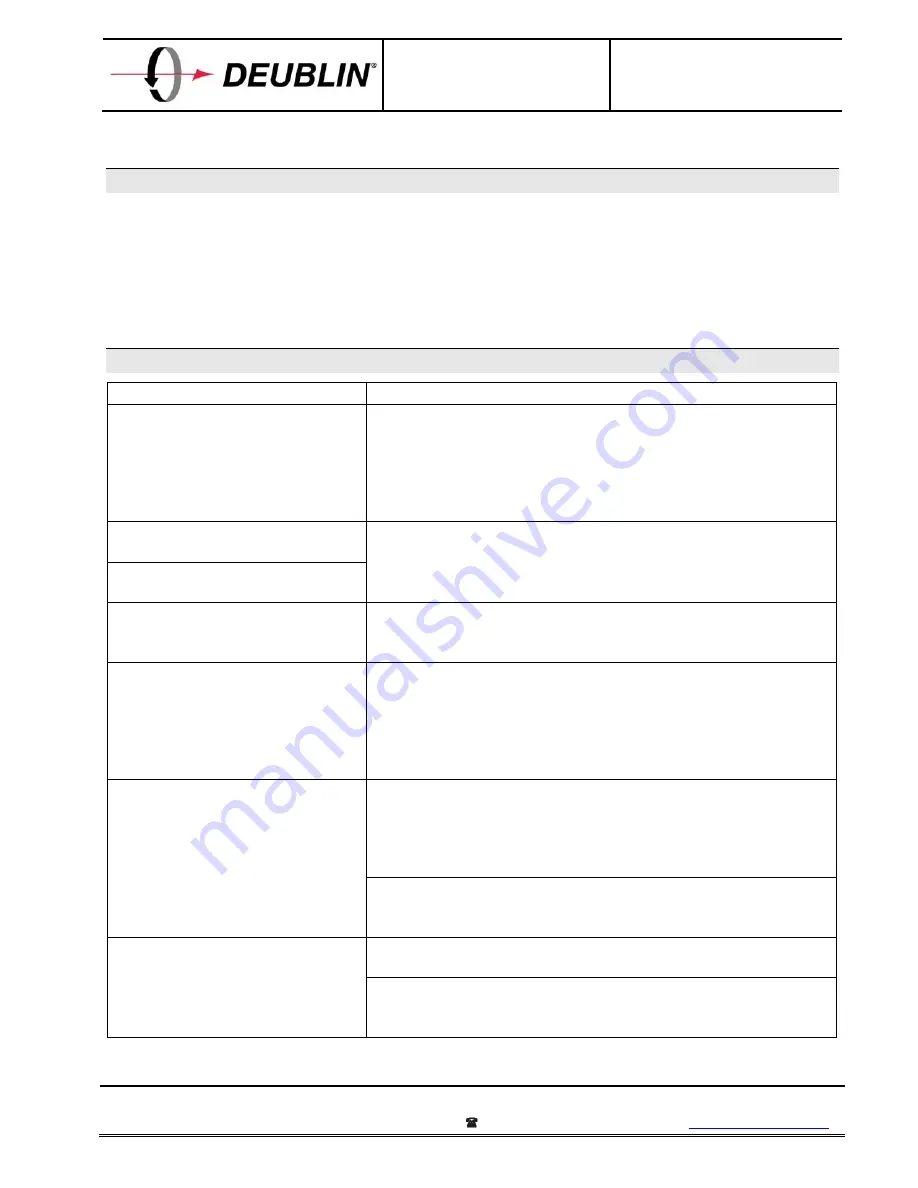

Troubleshooting

Problem Solution

Union temperature seems too high

immediately after installation.

Operating temperature may be higher than normal immediately after

installing the union, especially if the union is used immediately at

high RPMs without media. Generally, it is a good idea to “run in” a

new union in order to evenly distribute grease in the bearings. The

union will operate correctly without being run in, but it will run hot

for a little while.

Union temperature persistently

exceeds 50°C (122°F) after run-in.

Union makes a loud squeaking or

chirping noise at higher RPMs.

The seals may be running dry and probably are damaged. This can

happen, for example, if air for cleaning the tool taper blows through

the spindle and trapped pressure is not released after the tool

change. The union should be replaced immediately.

Union makes a loud buzzing or

rattling noise at higher RPMs.

The bearings may be damaged. This can happen when the drain

hose is blocked or does not have a continuous downward slope.

The union should be replaced immediately.

A few milliliters of coolant flow

from the drain hose at the beginning

of each tool change.

This is normal. Pop-Off™ seals close when coolant pressure is

applied and open when pressure is removed. After using through-

spindle coolant, media remaining in the spindle and supply hose

will drain out from the union. This feature eliminates friction and

seal wear during operation without coolant, and allows unlimited

“dry running” at any speed.

Media pressure and flow are insufficient to close the seals. Media

pressure at the union must be at least 1.5 bar to close the seals, with

an initial flow of at least 1.5 L/min. Measure media pressure at the

coolant supply connection and increase system pressure as

necessary.

Coolant flows from the drain hose

for several seconds, or more, after

coolant pressure is turned on, then

stops eventually.

Contaminants in the media are jamming the seals and preventing

proper closing. Check the filtration system and replace the filter as

necessary.

The seals have been damaged or have reached the end of their

useful life. The union should be replaced immediately.

Coolant flows continuously from

the drain hose during operation with

through-spindle coolant.

Media pressure and flow are insufficient to close the seals. Media

pressure at the union must be at least 1.5 bar to close the seals, with

a flow of at least 1.5 L/min.