48

8-2 ENGINE STOPS DURING OPERATION

(1) IF THERE IS SOMETHING WRONG WITH THE COMPRESSOR:

Pressure setting is too high.

Pressure regulator is not correctly adjusted

…

Lower pressure setting of the regulator.

pressure regulator is defective

…

Call service shop.

Air leaks from pressure regulator pipes

…

Check and repair leaking portions.

Pressure regulator is frozen

…

Check and repair frozen parts.

Pressure regulator pipes are frozen

…

Check and repair frozen parts.

Others.

Compressor oil is excessively

…

Replace with less viscous oil.

(2) IF THERE IS SOMETHING WRONG WITH THE ENGINE:

Problems in fuel system

Fuel tank is empty

…

Replenish.

Air is not fully extracted

…

Fully extract air from fuel.

Fuel filter is clogged

…

Replace.

Fuel is deteriorated or different

…

Use light oil.

Fuel injection system is defective

…

Call service shop.

Engine oil level is higher than the upper limit

…

Reduce it to the upper limit.

Engine oil is excessively viscous

…

Replace with less viscous oil.

Engine oil pressure is reduced

…

Replenish.

Overheating

…

Compressor sucks exhaust gas from

other compressors operated in parallel.

Others.

Warming is insufficient viscous

…

Start the engine with the unloader valve

set to the “START” position to fully warm

the engine.

Governor rod is not correctly adjusted

…

Readjust.

Summary of Contents for DIS-390ES

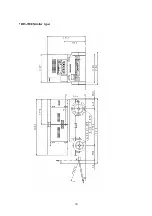

Page 58: ...55 10 2 Outline drawing DIS 390ES...

Page 59: ...56 DIS 390ES trailer type...

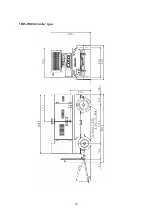

Page 60: ...57 DIS 390ES C...

Page 61: ...58 DIS 390ES C trailer type...

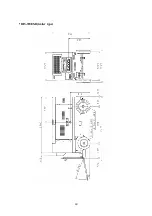

Page 62: ...59 DIS 390ES D...

Page 63: ...60 DIS 390ES D trailer type...

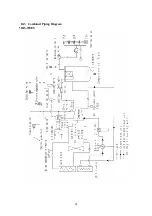

Page 64: ...61 10 3 Combined Piping Diagram DIS 390ES...

Page 65: ...62 DIS 390ES C...

Page 66: ...63 DIS 390ES D...

Page 67: ...64 10 4 Engine wiring diagram...