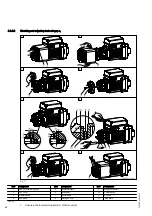

Trolley suspension

Fig. 14

Flange thickness t

[mm]

10

13

16

19

22

25

28

30

Number of washers, item (1)

0

1

2

3

4

5

6

7

Order no.

340 542 44

Bolt length, item (2)

[mm]

45

50

55

65

Order no.

300 250 44

300 251 44

300 252 44

300 253 44

Tab. 22

Adjusting the curve travel guide arm

The position of the lower anti-tilt guide roller must be adjusted to the given flange thickness by means of a slot.

The roller must be secured in such a way that an optimum play of approx. 1 mm is achieved. The curve travel

guide arm must not bind at any point along the track; push the trolley along the entire track by hand to check that

it does not bind. This check can only be carried out before the dished washer stack of the drive has been pre-

tensioned or when the pre-tension in the dished washer stack has been relieved by means of a disengaging de‐

vice.

5.7

Link bar

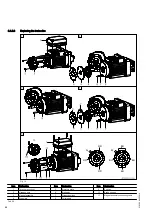

Fig. 15

Item

Designation

Item

Designation

A)

KBK I, II-L, II, II-H link bar, short for straight travel

B)

KBK I, II-L, II, II-H link bar, long for travel on curved tracks

C)

KBK III link bar, not for curved tracks

D)

KBK III link bar, for curved tracks

Tab. 23

The two trolleys connected for travel on a curved track must be arranged in such a way that the curve travel guide

arms are aligned towards the link bar, see

30

214

39

5 44/120

914

Summary of Contents for DRF 200

Page 51: ...214 395 44 120914 51...