8.

CR #24~ CR #27: means analog input voltage or current when conversion value from analog

signal to digital is 4000. Voltage setting range: -4V~+20V(-3200

LSB

~+16000

LSB

). Current setting

range: -16mA~+52mA(-3200

LSB

~+10400

LSB

). But it needs to notice that GAIN VALUE –

OFFSET VALUE = +800

LSB

~+12000

LSB

(voltage) or +800

LSB

~+6400

LSB

(current). When this

value under this range, the resolution of the input signal will be thin and the variation of value

will be larger. When this value exceeds this range, the resolution of input signal will be thick

and the variation of value will be smaller.

9.

CR#30 is fault code. Please refer to the following chart.

Fault

description

Content b15~b8 b7 b6 b5 b4 b3 b2 b1 b0

Power

source

abnormal K1(H1)

0 0 0 0 0 0 0 1

Analog

input

value

error K2(H2)

0 0 0 0 0 0 1 0

Setting

mode

error

K4(H4)

0 0 0 0 0 1 0 0

Offset/Gain

error

K8(H8)

0 0 0 0 1 0 0 0

Hardware

malfunction

K16(H10)

0 0 0 1 0 0 0 0

Digital

range

error

K32(H20)

0 0 1 0 0 0 0 0

Average

times

setting

error

K64(H40)

0 1 0 0 0 0 0 0

Command error

K128(H80)

Reserved

1 0 0 0 0 0 0 0

Note: Each fault code will have corresponding bit (b0~b7). Two or more faults may happen at the same time.

0 means normal and 1 means having fault.

10. CR#31: it is used to set RS-485 communication address. Setting range is 01~255 and factory

setting is K1.

11. CR#32 is used to set RS-485 communication baud rate: 4800, 9600, 19200, 38400, 57600, 115200

bps. b0: 4800bps. b1: 9600bps. (factory setting) b2: 19200bps. b3: 38400 bps. b4: 57600 bps. b5:

115200 bps. b6-b13: reserved. b14: exchange low and high byte of CRC check code. (only for RTU

mode) b15=0: ASCII mode. b15=1: RTU mode.

12. CR#33 is used to set the inner function priority. For example: characteristic register. Output

latched function will save output setting in the inner memory before loss power.

13. CR#34: software version.

14. CR#35~ CR#48: system used.

15. The corresponding parameters address H4000~H4030 of CR#0~CR#48 can provide user to

read/write data by RS-485.

A. Communication baud rate: 4800, 9600, 19200, 38400, 57600, 115200 bps.

B. Communication format: ASCII mode is 7Bit, even bit, 1 stop bit (7 E 1). Communication

format of RTU mode is 8Bit, even bit, 1 stop bit (8 E 1).

C. Function code: 03H—read data from register. 06H—write a WORD into register. 10H—write

many WORDs into register.

5

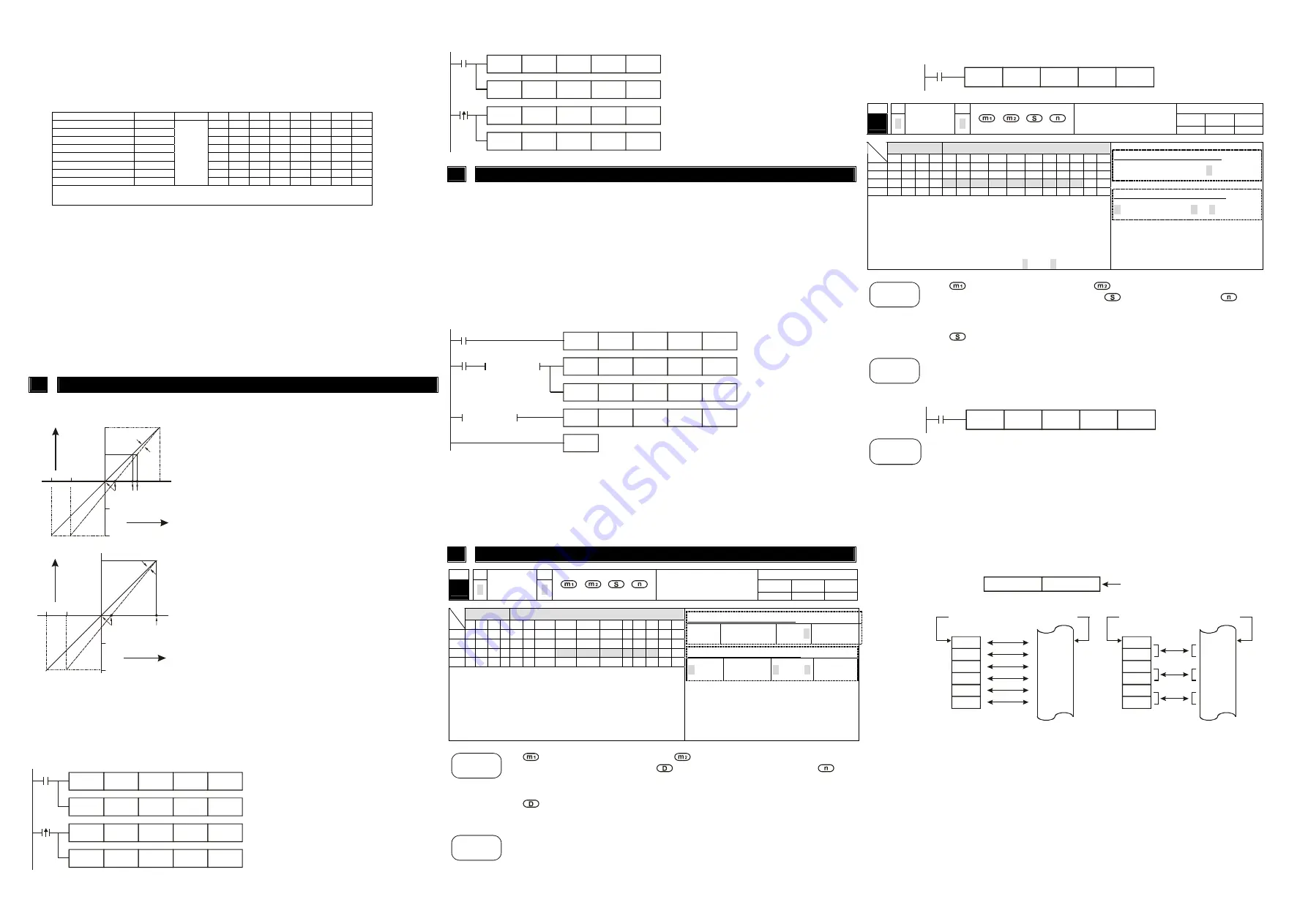

Adjust A/D Conversion Characteristic Curve

5.1 Adjust A/D Conversion Characteristic Curve

Voltage input mode

Mode 0 of CR#1 GAIN=5V(4000

LSB

), OFFSET=0V (0

LSB

)

Mode 1 of CR#1 GAIN=6V(4800

LSB

), OFFSET=2V (1600

LSB

)

GAIN:

Voltage input value when digital output is

4000. Setting range is -4V~+20V(-3200

LSB

~

+16000

LSB

)

OFFSET:

Voltage input value when digital output is 0.

Setting range: -5V~+5V(-4000

LSB

~

+4000

LSB

)

+8000

+4000

-4000

10V

-8000

-6V

-10V

6V

5V

2V

0

GAIN

OFFSET

Digital

output

Mode 0

Mode 1

Voltage input

GAIN

-

OFFSET: Setting range is +1V~+15V (+800

LSB

~

+12000

LSB

)

Current input mode

Mode 2 of CR#1: GAIN = 20mA(4000

LSB

), OFFSET=4mA

(800

LSB

).

Mode 3 of CR#1: GAIN = 20mA(4000

LSB

), OFFSET=0mA

(0

LSB

).

GAIN:

Current input value when digital output is

+4000. Setting range is -20 mA~+20 mA

(-4000

LSB

~ +4000

LSB

)

OFFSET:

Current input value when digital output

value is 0. Setting range is-16 mA ~+52 mA

(-3200

LSB

~ +10400

LSB

)

+4000

-4000

-12mA

-20mA

4mA

0

OFFSET

20mA

GAIN

Digital

output

Mode 3

Mode 2

Current input

GAIN

-

OFFSET: Setting range is +4mA ~ +32mA (800

LSB

~

+6400

LSB

)

The chart above is to adjust A/D conversion characteristic curve of voltage input mode and

current input mode. Users can adjust conversion characteristic curve by changing OFFSET values

(CR#18~CR#21) and GAIN values (CR#24~CR#27) depend on application.

LSB(Least Significant Bit): 1. voltage input: 1

LSB

=10V/8000=1.25mV. 2. current input:

1

LSB

=20mA/4000=5µA.

5.2. Program Example for Adjusting A/D Conversion Characteristics Curve

Example 1: setting OFFSET value of CH1 to 0V(=K0

LSB

) and GAIN value of CH1 to 2.5V(=K2000

LSB

).

X0

K2000

K24

H0

K1

K0

K1

H0

K1

M1002

K0

K33

K1

K0

K1

K18

K0

K0

TO

TO

TO

TO

Writing H0 to CR#1 of analog input

module no. 0 and set CH1 to mode 0

(voltage input -10V~+10V)

Writing H1 to CR#33 and allow to

adjust characters of CH1.

When X0 switches from OFF to ON,

K0

LSB

of

OFFSET value will be wrote in

CR#18 and K2000

LSB

of GAIN value

will be wrote in CR#24.

Example 2: setting OFFSET value of CH2 to 2mA(=K400

LSB

) and GAIN value of CH2 to 18 mA

(=K3600

LSB

)

X0

K1

K0

K1

H0

K1

M1002

K0

K33

K1

K0

K1

K0

H18

K19

K25

K400

K3600

TO

TO

TO

TO

Writing H18 to CR#1 of analog input mode

no. 0 and set CH2 to mode 3 (current input:

-20 mA ~ +20mA)

Writing H0 to CR#33 and allow to adjust

characteristics of CH4.

When X0 switches from OFF to ON,

K400

LSB

of

OFFSET value will be wrote in

CR#19 and K3600

LSB

of GAIN value will be

wrote in CR#25.

6

Initial PLC Start-up

Lamp display:

1.

When power is on, POWER LED will be lit and ERROR LED will be lit for 0.5 second.

2.

When it is normal that POWER LED should be lit and ERROR LED should turn off. When

power supply is lower than 19.5V, ERROR LED will blink continuously till the power supply

is higher than 19.5V.

3.

When it connects to PLC MPU in series, RUN LED on MPU will be lit and A/D LED or D/A

LED should blink.

4.

After receiving the first RS-485 command during controlling by RS-485, A/D LED or D/A

LED should blink.

5.

After converting, ERROR LED should blink if input or output exceeds upper bound or lower

than lower bound.

Example:

K1

K0

K1

K1

K0

K0

K0

M1000

FROM

TO

END

K2

K6

D0

H3030

K32

D20

K4

FROM

TO

K0

K2

= H88 D0

M1002

= H88 D0

Explanation:

Reading the data of model type from expansion module K0 and distinguish if the data is H88

(DVP04AD-S model type).

If the model type is DVP04AD-S, M11 is on and the setting input mode is (CH1, CH3)= mode 0,

(CH2, CH4)= mode 3.

Setting the average times of CH1 and CH2 are K32.

Reading the input signal average value of CH1~CH4 (4 data) saving in D20~D23.

7

Related Instructions Explanation

API

Adaptive model

ES EP EH

78

D

FROM

P

Special module CR

data read out

Bit device

Word device

X Y M S K H KnX KnY KnM KnS T C D E F

m

1

¼

¼

m

2

¼

¼

D

¼

¼

¼

¼ ¼ ¼ ¼

¼

n

¼

¼

Note: The usage range of operand m

1

is 0~7.

The usage range of operand m

2

: ES/EP:

0-48, EH: 0-254.

The usage range of operand n: ES/EP: n=

1~(49-m2), EH: 1~(255-m2).

ES series model doesn’t support pulse

execution command (FROMP, DFROMP).

16-bit command (9 STEPS)

FROM

Continuous

execution

FROMP

Pulse

execution

32-bit command (17 STEPS)

DFROM

Continuous

execution

DFROMP

Pulse

execution

Flag: When M1083=On, it allows to

insert interrupt during

FROM/TO.

Refer to following for detail.

Command

Explanation

: the number for special module.

: the number of CR (Control Register) of

special module that will be read.

: the location to save reading data.

: the

data number of reading one time.

DVP-series PLC uses this command to read CR data of special module.

: When assigning bit operand, K1~K4 can be used for 16-bit and K5~K8 can be

used for 32-bit.

Please refer the following footnote for calculating of special module number.

Program

Example

To read the content of CR#24 of special module#0 to D0 of PLC and to read the

content of CR#25 of special module#0 to D1 of PLC. It can read 2 data in one time

(n=2).

The command will be executed when X0=ON. The command won’t be executed

when X0=OFF and the content of previous reading data won’t change.

X0

FROM

K0

K24

D0

K2

API

Adaptive model

ES

EP

EH

79

D

TO

P

Special module CR

data write in

Bit device

Word device

X

Y

M S K H KnX KnY KnM KnS T C D E

F

m

1

¼

¼

m

2

¼

¼

S

¼

¼

¼

¼

¼

¼

¼

¼

¼

¼

¼

n

¼

¼

Note: The usage range of operand m

1

is 0~7.

The usage range of operand m

2

: ES/EP: 0-48,

EH: 0-254.

The usa ge range of operand n: ES/EP: n=

1~(49-m2), EH: 1~(255-m2).

For ES series, it doesn’t support pulse

execution command (TOP, DTOP)

16-bit command (9 STEPS)

TO

Continuous

execution

TOP

Pulse

execution

32-bit command (17 STEPS)

DTO

Continuous

execution

DTOP

Pulse

execution

Flag: When M1083=On, it allows

to insert interrupt during

FROM/TO.

Refer to following for detail.

Command

Explanation

: the number of special module.

: the number of CR (Control Register)

of special module that will be wrote in.

: the data to write in CR.

: the

data number to write in one time.

DVP-series PLC uses this command to write data into CR of special module.

: When assigning bit operand, K1~K4 can be used for 16-bit and K5~K8 can

be used for 32-bit.

Program

Example

Using 32-bit command DTO, program will write D11 and D10 into CR#3 and CR#2

of special module#0. It only writes a group of data in one time (n=1).

The command will be executed when X0=ON and it won’t be executed when

X0=OFF. The data that wrote in previous won’t have any change.

X0

K0

K2

D0

DTO

K1

Footnote

The rule of command operand:

m1: arrangement number of special module. The number of special module

that connects to PLC MPU. The numbering order of special module from the

near to the distant of MPU is from 0 to 7. The maximum is 8 special modules

and won’t occupy I/O point.

m2: the number of CR. Built in 16-bit of 49 groups memory of special module

is called CR (Control Register). The number of CR uses decimal digital

(#0~#48). All running status and setting values of special module has

included.

If using FROM/TO command, the unit of read/write of CR is one number for

one time. If using DFROM/DTO command, the unit of read/write of CR is two

numbers in one time.

CR #10

CR #9

Upper 16-bit Lower 16-bit

Specified CR number

The number of transmission groups n. The meaning of n=2 of 16-bit command

and n=1 of 32-bit are the same.

D0

D1

D2

D3

D4

D5

CR #5

CR #6

CR #7

CR #8

CR #9

CR #10

D0

D1

D2

D3

D4

D5

CR #5

CR #6

CR #7

CR #8

CR #9

CR #10

Specified device

Specified CR

Specified device Specified CR

16-bit command when n=6

32-bit command when n=3

In ES series models, flag M1083 is not provided. When FROM/TO command is

executed, all interrupts (including external or internal interrupt subroutines) will be

disabled. All interrupts will be executed after FROM/TO command is completed.

Besides, FROM/TO command also can be executed in the interrupt subroutine.

The function of the flag M1083 (FROM/TO mode exchange) provided in EP/EH

series models:

1. When M1083=Off, FROM/TO command is executed, all interrupts (including

external or internal interrupt subroutines) will be disabled. All interrupts will be

executed after FROM/TO command is completed. Besides, FROM/TO

command also can be executed in the interrupt subroutine.

2. When M1083=On, if an interrupt occurs while FROM/TO command has been

programmed, FROM/TO command will be interruptted to execute the interrupt.

However, FROM/TO command cannot be executed in the interrupt subroutine.