Page 14

Conveyor Operation Summary

Operation

◼

Place the Conveyor on top of the light box.

◼

Avoid bright ambient light and sunlight.

◼

Adjust the belt tension

– see Belt Tension Adjustment.

◼

Slide guide rods into position.

◼

Run WinDIAS software, and optimise camera, lens and threshold.

◼

Click on the

Calibrate

tool and calibrate with ruler.

◼

Toggle

Conveyor

on in the

Area

Control Window.

SLACKEN THE BELTS AT FINISH

Belt Speed Selection

◼

Choose the fastest speed that does not blur the image.

◼

Set the camera shutter to around 1-10 ms.

◼

The image should take about two seconds to cross the screen.

◼

Drop the idlers pulley in its slot to release the drive band tension.

◼

Remove the knurled nut from the motor shaft.

◼

Fit the desired pulley and lock it in place.

◼

Re-tension the drive band to eliminate slip. Do not over-tighten.

◼

Keep all liquids away from the drive band and pulleys.

Belt Removal

De-tension the belts.

Remove the line-guides.

Unlock and release the roller shafts.

Lift out each belt and its pair of rollers.

On re-assembly, locate the bottom roller inside the rubber drive band.

Belt Renewal and Cleaning

◼

Cut the new material to length - top belt: 80 cm, bottom belt:104 cm.

◼

Make a butt-joint using clear adhesive tape on both sides.

◼

Clean the belts with anti-static spray or a damp soft cloth.

◼

Avoid abrasive cleaners and solvents.

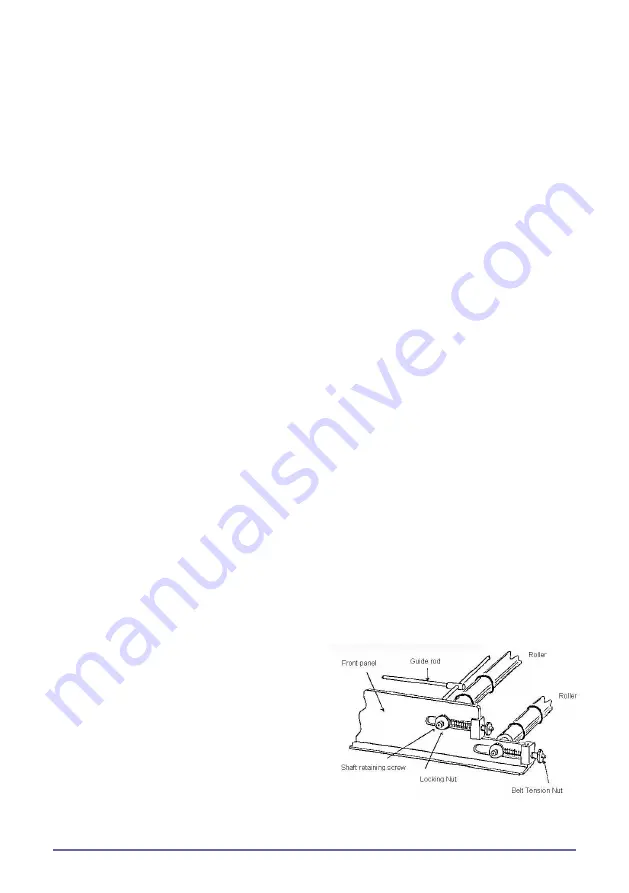

Belt Tension Adjustment

The upper and lower conveyor belts are

tensioned with four belt-tensioning nuts.

Initially the belt tension should be minimal.

Ensure that the tension is even and that the

belts are centred.

Inspect the belts for ripples - this indicates

uneven or excessive tension.

SLACKEN THE BELTS AT FINISH