10

®

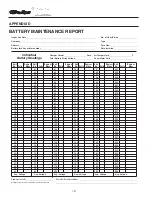

APPENDIX D

BATTERY MAINTENANCE REPORT

Charger Output _____________________ Amp

Air Temperature ______________________°F

Total Battery String Voltage ________________

Panel Meter Volts ______________________

Unit

Ohms or Unit

Ohms or Unit

Ohms or Unit

Ohms or Unit

Ohms or Unit

Ohms or

No. Volts Mhos No. Volts Mhos No. Volts Mhos No. Volts Mhos No. Volts Mhos No. Volts Mhos

Inspection Date _____________________________________________________________________

No. of Units/String __________________

Company ___________________________________________________________________________ Type _______________________________

Address ____________________________________________________________________________

Date New __________________________

Battery location and/or number ______________________________________________________

Date Installed _______________________

Readings Taken By ____________________________ Remarks/Recommendations __________________________________________________________

Readings should be taken at installation and annually thereafter.

_________________________________________________________________________________

1

41

81

121

161

201

2

42

82

122

162

202

3

43

83

123

163

203

4

44

84

124

164

204

5

45

85

125

165

205

6

46

86

126

166

206

7

47

87

127

167

207

8

48

88

128

168

208

9

49

89

129

169

209

10

50

90

130

170

210

11

51

91

131

171

211

12

52

92

132

172

212

13

53

93

133

173

213

14

54

94

134

174

214

15

55

95

135

175

215

16

56

96

136

176

216

17

57

97

137

177

217

18

58

98

138

178

218

19

59

99

139

179

219

20

60

100

140

180

220

21

61

101

141

181

221

22

62

102

142

182

222

23

63

103

142

183

223

24

64

104

144

184

224

25

65

105

145

185

225

26

66

106

146

186

226

27

67

107

147

187

227

28

68

108

148

188

228

29

69

109

149

189

229

30

70

110

150

190

230

31

71

111

151

191

231

32

72

112

152

192

232

33

73

113

153

193

233

34

74

114

154

194

234

35

75

115

155

195

235

36

76

116

156

196

236

37

77

117

157

197

237

38

78

118

158

198

238

39

79

119

159

199

239

40

80

120

160

200

240

Avg. Voltage

Avg. Voltage

Avg. Voltage

Avg. Voltage

Avg. Voltage

Avg. Voltage

Individual

Battery Readings