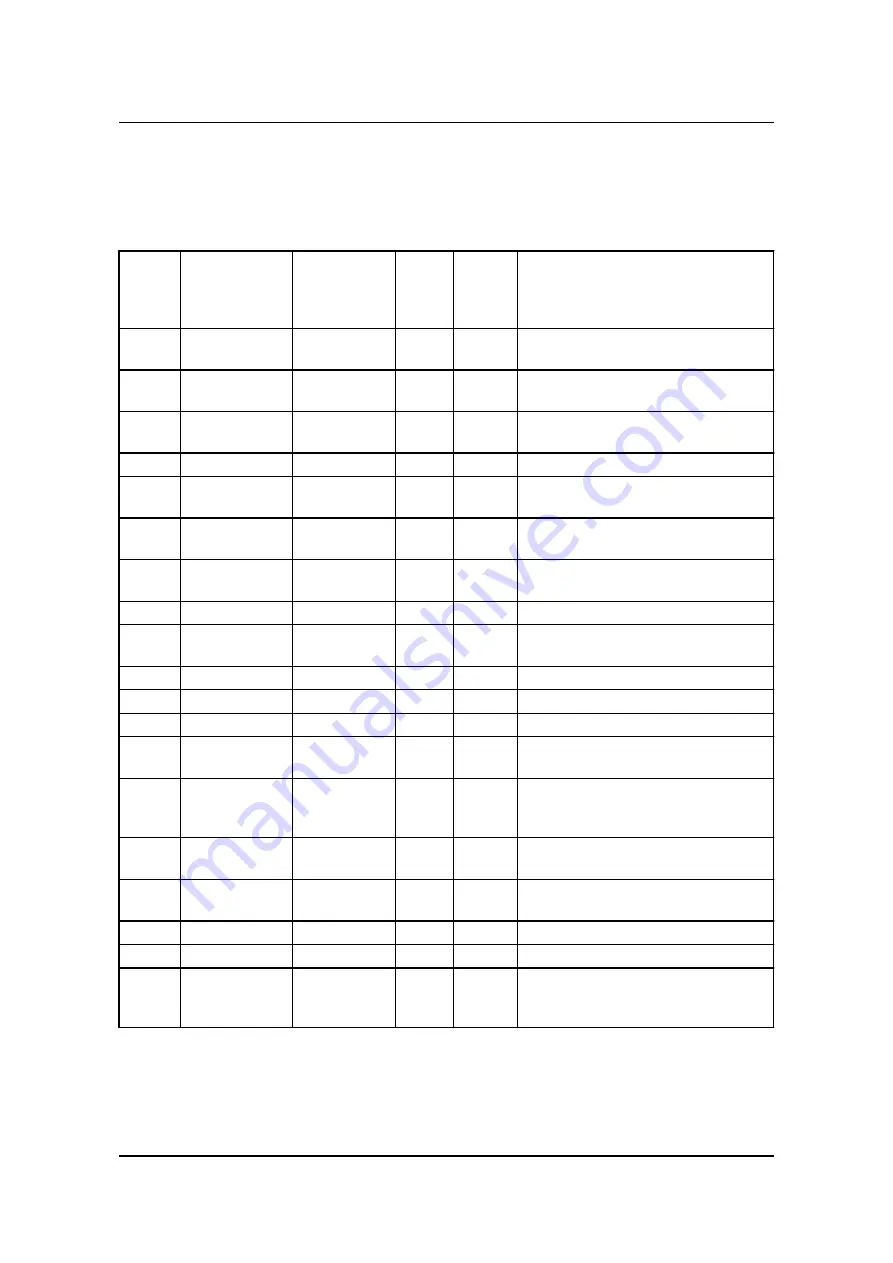

4.1.2 Parameter list

The parameters used by CGC 200 that can be changed from the controller front panel are listed in the table

below.

Param-

eter

num-

ber

Parameter

name

Range

De-

fault

value

Value

chos-

en*

Description

P00

Auto start delay

0 to 3600 s

1

Timer for starting using the Auto start

signal

P01

Auto stop delay

0 to 3600 s

1

Timer for stopping after the Auto start

signal is removed

P02

Start attempts

1 to 10

3

Number of start attempts in one start se-

quence

P03

Start prepare

0 to 300 s

0

Timer for start prepare

P04

Start on time

3 to 60 s

8

Timer for starter ON time during crank-

ing

P05

Start off time

3 to 60 s

10

Timer for starter OFF time before a new

start attempt is made

P06

Initial inhibit de-

lay

1 to 60 s

10

Timer for bypassing frequency and volt-

age shutdown during starting

P07

Idle start

0 to 3600 s

0

Timer for idle speed after starting

P08

GB close delay

3 to 3600 s

10

Timer for generator breaker close after

frequency and voltage OK

P09

Cooldown time

3 to 3600 s

10

Cooling down time

P10

Idle stop

0 to 3600 s

0

Timer for idle speed before stopping

P11

Extended stop

0 to 120 s

20

Timer for extended stop

P12

Stop failure

0 to 120 s

0

Maximum allowable time for stopping

the genset

P13

Number of teeth

10 to 300

118

The number of teeth on flywheel. This is

only used when MPU is selected as run-

ning detection (see

P40

).

P14

Number of gen.

poles

2 to 32

4

The number of genset poles. This is

used in the frequency calculation.

P15

Hz/V OK delay

0 to 20.0 s

10.0

Voltage and frequency OK delay after

starting of genset

P16

G U >

30 to 360 V

264

Generator over-voltage protection

P17

G U <

30 to 360 V

196

Generator under-voltage protection

P18

G RPM <

0 to 6000

RPM

1200

Generator under-speed protection, if

running detection (see

P40

) is RPM in-

put only

CGC 200 Operator's manual 4189340770

UK

Parameters

DEIF A/S

Page 15 of 43