5

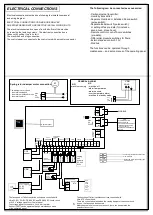

Input,

230V,

50 Hz

10 A

-power

cord

(plug)

+24

0

0-10

CO2/%RH1

+24

0

0-10

CO2/%RH2

0-10

+24

0

0-10 +24

0

+24

0

WINTER

YHT

SUMMER

NC

YHT

NO

G

+

G

0

O

U

T

1

CO2

sensor

0

0

-1

0V

COOKER HOOD

0-10v voltage signal

0

0

-1

0V

PC EC

PG EC

230V,

50 Hz

10 A

KTS

NO

COM

NC

open

closed

cooling

coil

actuator

DC 24 V

0-10v

A

L

A

R

M

NC

YH

T

NO

M

max.

8A

250V

L

N

230 V

max.

8A

250V

NO

- machine running

NC

- machine off

- alarm temperatures

- alarm sensors

- over-temperature alarm

- machine in standby mode

NC

YH

T

NO

max.

8A

250V

VAK

NO NC

GENERAL ALARM

A

L

A

R

M

HUMIDITY

TRANSMITTER

VS+ GND

RH

overpressure

setpoint 0

tip of the data in

M

O

D

B

U

S

A/D+

B/D-

0

MODBUS

O O O

O O O

O O O

ON OFF BIAS B

ON OFF Term

ON OFF BIAS A

ALARM INDICATION

AND OPERATING

POTENTIAL FREE CONTACT

INFORMATION MACHINE

OR CONTROL OF

SPRING RETURN DAMPER

MOTOR

P

u

ls

e

s

w

it

c

h

s

w

it

c

h

P

u

ls

e

s

w

it

c

h

P

re

su

re

sw

itc

h

e

s

switch

switch

boosting

setpoint 0

tip of the data in

COOKER HOOD

boosting information

Operator panel

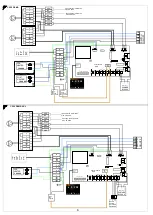

Spring return damper motor connection

The damper motor closes

- the machine stopped

- the machine in standby mode

- the machine alarm

al

ar

m

su

m

m

e

r

b

yp

a

ss

sensor 1

sensor 2

overpressure/

extended

time

boosting

out-of house/

remote

filter

cooling

water radiator

The fan speed of Talteri ventilation unit can be controlled with

Ultra PC EG, PG EC, DS-600 EC and DSA-900 EC cooker hood

or 0-10 V voltage signal from Control panel.

The voltage signal connected to

CO2/%RH1

terminal.

Sensor 1(EXT) can be operated through maintenance menu

of the operating panel.

The boosting of Talteri ventilation unit can controlled with

Ultra KTS cooker hood.

There is a control panel and when the closing damper of the cooker hood

is open the fan speed is enhanced.

Maintenance menu is used to set boost 0, there can be operated the

guantity of boost too.

ELECTRICAL CONNECTIONS

Electrical connections must be done following the installation manual

and wiring diagram.

ELECTRICAL CONNECTIONS CAN BE DONE ONLY BY

AN ENTREPRENEUR WITH RESPECTIVE INSTALLATION RIGHTS.

The electrical connection box opens from the bottom of the machine

by removing the fastering screws . The electrical connection box is

taken out by pulling it up to its limit.

The machine has a plug connection.

The control panel is connected to the control card with a modular connector.

The following can be connected as accessories:

- Carbon dioxide transmitter;

- Humidity transmitter;

- Separate Overload or Extended Period switch

(pulse switch);

- Separate Boost switch (pulse switch);

or setting off as pre-data (for instance,

sauna oven, stove hood);

- Remote control or out-of-home switches

(pre-data);

- Differential pressure switches for filters;

- External speed control 0-10V.

- Modbus.

The functions can be operated through

maintenance – and setup menus of the operating panel.

COM

NC

COM

NC

contact tip information extract fan

max. 2A 250V

contact tip information supply fan

max. 2A 250V

VAK

VAK