19

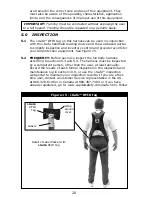

Step 4. Reach between your legs and grasp the gray leg strap on

your left side. Bring the strap up between your legs and

insert the tab of the buckle into the receptor of the buckle

on the left side as shown in Figure 13. You will hear a click

when the tab engages properly. Connect the right leg strap

using the same procedure. Pull the free end of the strap

away from the buckle to make a snug fit on each leg strap.

To loosen the leg strap, grasp the yellow plastic portion of

the buckle and pull away from your leg to allow the strap

to pull through the buckle. A plastic end keeper on the end

of the strap will stop it from pulling completely out of the

buckle. To release the buckle, press the silver-colored tabs

on the buckle towards each other with one hand, while

pulling on the tab portion of the buckle with the other hand.

Step 5. Adjust shoulder strap to a snug fit by pulling excess strap

through the parachute buckle. Left and right sides of the

shoulder straps should be adjusted to the same length

and the front D-ring should be centered on your lower

chest. The back D-ring should be centered between your

shoulder blades. Note: On ExoFit XP models, the back

(dorsal) D-ring can be repositioned up or down as needed

for a correct fit. Adjust the leg straps to a snug fit. At least

3 in. (8 cm) of webbing must extend past the buckle on

the leg straps. Adjust the waist belt (if present).

3.4 USE OF FALL ARREST D-RING OR ATTACHMENT ELEMENT:

For fall protection applications connect to the D-ring or attachment

element on your back, between your shoulder blades. Side

D-rings, if present, are for positioning or restraint applications

only. Front D-ring, if present, is for ladder climbing or positioning.

For rescue, back or front D-rings may be used. D-rings on seat

sling are for work positioning or personnel riding.

3.5 MAKING CONNECTIONS:

When using a hook to connect to an

anchorage or when coupling components of the system together,

ensure roll-out cannot occur. Roll-out occurs when interference

between the hook and mating connector causes the hook gate

to unintentionally open and release. Self-locking snap hooks and

carabiners should be used to reduce the possibility of roll-out. Do

not use hooks or connectors that will not completely close over the

attachment object. See subsystem manufacturer’s instructions for

more information on making connections.

3.6 CONNECTING SYSTEM COMPONENTS:

After properly fitting

the full body harness, the user may then connect to other system

components. Follow the guidelines in section 3.4 on selecting the

correct attachment element.

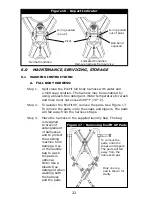

4.0 TRAINING

4.1

It is the responsibility of the purchaser and the user of this

equipment to assure that they understand these instructions and