4

INSTALLATION PROCEDURE

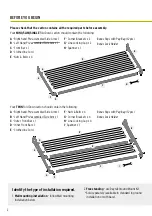

1. MOUNT SIDE ARMS TO WALL

Note: For ground mount kits installation skip

to step 1.4

1.1

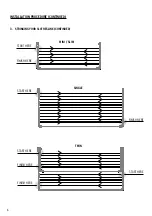

Mark wall bracket positions and centres

. Refer

to Figure 1 for fixing centres measurements for

the model you are installing. The vertical distance

between wall bracket mounting holes is 170mm.

Take note of the recommended installation height.

1.2

Use 8mm x 50mm masonry anchors or suitable

wood screws to fasten to your selected surface.

Consult a hardware store or builder if unsure.

1.3

Drill holes suitable to your chosen fixings

squarely into your wall at the marked location.

1.4

Fix the pre-assembled Side Arms to the wall.

Note the Left and Right hand assemblies (Daytek

logo should always be upright – refer to Fig. 1A)

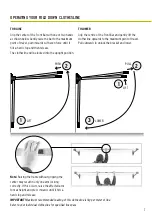

2. CONNECT CORNER BRACKETS

AND FRONT BAR

1A

2A

2C

2E

2B

2D

2F

TO DETERMINE LEFT

AND RIGHT

PRE-ASSEMBLED

SIDE ARMS ALWAYS

ENSURE DAYTEK

LOGO ON BRACKET

IS UPRIGHT AND

LINE BRACKETS ARE

FACING INWARDS

2.1

Attach a Corner Bracket over

each end of the Front Bar and

secure with the supplied nuts &

bolts

(See Fig. 2A – 2C). For Twin

model, assemble and attach the

Inner Front Bar first (shorter one).

2.2

Lock each side arm into the

upright position.

To do this lift

each side arm upwards to the

maximum point of travel and push

inwards until it hits a hard stop, then

release (refer to operating diagrams

on page 7).

2.3

Install Front Bar to the Side Arms

and secure with supplied nuts &

bolts

(See Fig. 2D – 2F).