8 FIRST OPERATION

1

Boiler Selection Knob

2

Computer Connection Inlet

3

Exit

4

Reset

5

Manual Control Knob

6

Pipe Function Knob

7

Confirm Button

8

Set Button

9

Information Button

10 Operation Mode Selection

Button

11 LCD Display

8.1 Heating Mode Selection

When you press operation mode selection

(number 10) knob, you can make passing

between modes that are explained in the

following.

Modes are;

OFF

Concort Mode

Night Mode

Automatic Mode

OFF: Device waits in standby mode. Except

freezing prevention it does not operate any

function.

Comfort Mode: Operates according to set

temperature.

Night Mode: Operates according to set

temperature.

Automatic Mode: Enables to operate depending

hour time. General operation mode of the system

will be this.

8.2 Setting Time Hour

1-

It is entered to submenu by pressing

confirm button (number 7) while it is in

home screen of device.

2-

It is entered to “Time program of heating

cycle 1” menu by pressing OK button.

3-

Firstly, it is chosen for which day’s

program will make. You can make

passing between options with Set Button

(number 8). When you come to your

demanded days, make your choosing

with OK button.

4-

Set the operation start hour and press

the OK button.

5-

Then set operation finish hour and press

OK button.

6-

Return to home screen by ESC button

after you chose AUTO, your device will

start to operate according to set

operation hour.

8.3 Room Temperature Setting

While the device is in home screen, turn the

number 8 button. Temperature values will be

appearing at the display. Exit from menu with OK

button after you bring your demanded value.

8.4 Manual Using

It is used for operating device independent from

auto operation mode. Manual control can be

activated or passivity with number 5 knob.

Intended boiler temperature can be set from info

menu.

8.5 Reset

When your device goes out of order, error

description is written on the display and passes to

standby mode. Do not forget that, this device can

be gone out of order at gas leakage and

installation failures. After making control of

these, try restart again by pressing number 4

reset knob. After trying 3 times if the device has

still not operated, contact with authorized

service.

9. MAINTENANCE

As well as it changes using place and using

conditions, it is preferred to have your device

maintenance done once a year.

It is importantly preferred, have your boiler

maintenance done by authorized service agency

and using original parts while changing necessary

parts. Do not forget that your device will be out

of warranty in case of intervention of authorized

personnel or using parts which are not original.

It is needed to have your installation control

made together with boiler maintenance for

unproblematic operation of the system.

Summary of Contents for Navidens 50

Page 1: ......

Page 6: ...2 4 Dimension of Device Navidens 50 70...

Page 8: ...2 5 Boiler Installation Distances...

Page 14: ...Concentric Pipe System Double Pipe System...

Page 15: ...4 Sample Installation Diagram 4 1 Heating System with Boiler...

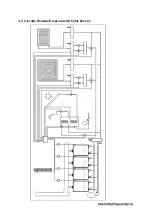

Page 16: ...4 2 Cascade Heating Diagram with Solar Energy...

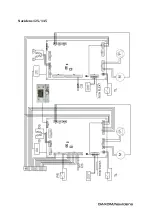

Page 18: ...6 ELECTRIC PROJECT Navidens 50 70...

Page 19: ...Navidens 125 145...