6 | Troubleshooting

Workstation Series User’s Guide

60

Note:

To clear errors, open the printer cover fully and then close and latch it.

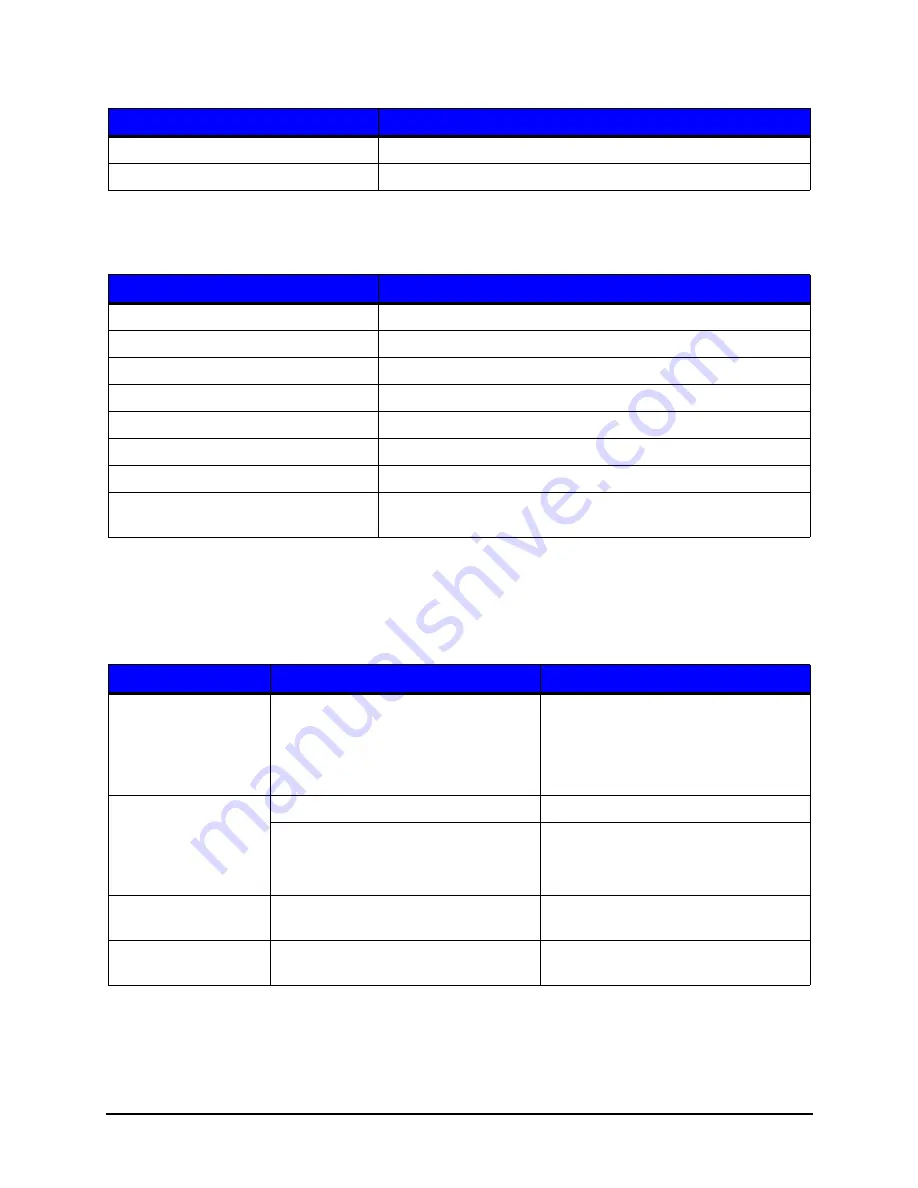

Warnings

Troubleshooting

The following chart provides basic troubleshooting steps for diagnosing problems with

the printer. If the symptoms remain after troubleshooting, contact your technical support

representative.

PRESENT SENSOR HARDWARE

Present sensor hardware fault

HEAD UP

Printing or feeding with the cover open

Warnings

Description

MAINTENANCE REMINDER

Maintenance timer has expired

POWER SUPPLY HARDWARE

Printhead voltage above maximum specifications

POWER SUPPLY LOW

Printhead voltage below minimum specifications

PRINTER COOLING

The printer is cooling

PAPER CALIBRATION MARGINAL

Paper sensor calibration marginal

PERFORM CALIBRATE SENSORS

There is a need to run Sensor Calibration

COVER OPEN

The printer cover is open and should be latched

PRESENT SENSOR NOT

INSTALLED

The present sensor is enabled but not installed

Symptom

Causes

Solutions

System Error

Incorrect label format or

communication is too slow.

1.

Connect to a different input port.

2.

Analyze the label format.

3.

Try a different label design

method.

Out of Paper

The printer may be out of media.

Install a new media roll.

The media is too transparent to be

detected.

1.

Perform “Calibrate Sensors.”

2.

Check the “TOF Sensor” reading

in the “Extended Status” utility.

FPGA Hardware

The main controller board may be

faulty.

Contact your technical support

representative.

NV RAM Hardware

The main controller board may be

faulty.

Contact your technical support

representative.

Errors

Description

Summary of Contents for Workstation w1110

Page 1: ...Workstation Series User s Guide ...

Page 2: ......

Page 4: ...Workstation Series User s Guide ...

Page 31: ...Connections and Setup 3 23 Workstation Series User s Guide ...

Page 32: ...3 Connections and Setup Workstation Series User s Guide 24 ...

Page 38: ...4 Operation Workstation Series User s Guide 58 ...

Page 40: ...5 Cleaning and Maintenance Workstation Series User s Guide 58 ...