19

Common Settings:

Name

Value

New value

1

Continuous Label

Length (1/100 inch)

425

Distance the printer will advance after pressing the FEED button.

Distance is measured in 1/100 inch. i.e. 1000=10 inches.

2

Label Width (1/100

inch)

425

200 = 2 inch media

300 = 3 inch media

400 = 4 inch media

3

Maximum Label Length

(1/100 inch)

800

Distance must be greater than the length of your media. i.e. 1000=10

inches

4

Sensor Type

Continuous

Gap = Labels with gap

Continuous = Media with no gaps

Reflective = Labels with Q-Mark or black mark

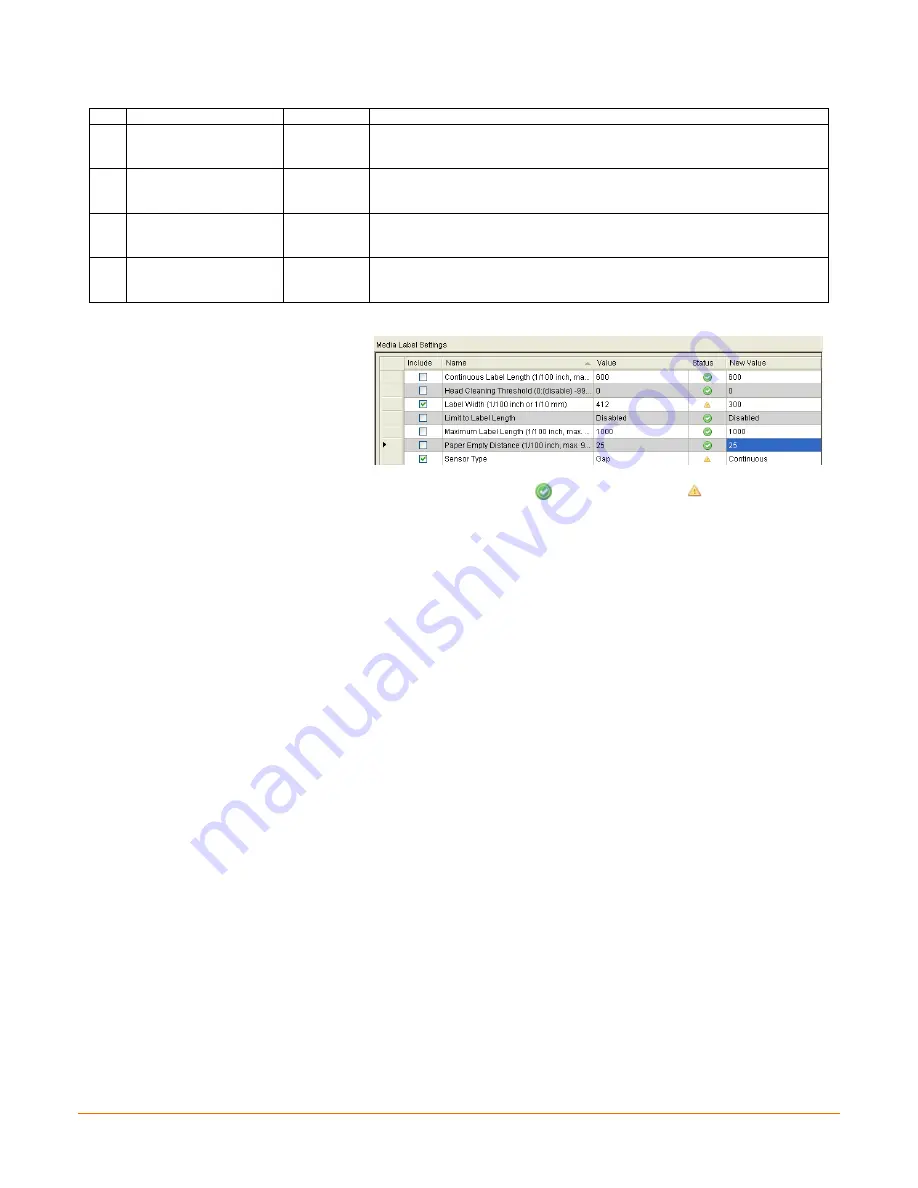

3) After updating the “New Value”

columns, click the Send button

to send these changes to the

printer.

Note: NETira CT will change its column status from a green

to orange triangle

when values are

modified and does not match current printer values.

Summary of Contents for RL3

Page 1: ...User Guide ...

Page 2: ......

Page 6: ......

Page 42: ...34 ...

Page 48: ...A 4 ...

Page 70: ......