-13

-12

-11

-10

-9

-8

-7

-6

-2

-1

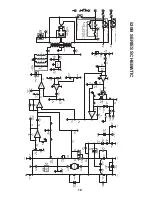

JUMPER WIRE (JU2) *

-5

-4

-3

P2

CURRENT

SOURCE

LINEARITY ADJUSTMENT

+ -

P16

250/500

-1 -2

125

(530B SERIES TERMINAL STRIP)

-5 Option

Available on “C” and “RC” models only

∗

Isolated 4-20 ma.Signal Follower

Factory or Field installed

12

Setting the Min, Max and Linearity Trimpots.

1.

Preset the multi-turn Linearity trimpot on the –5 option board full CW, set the Min trimpot full CCW and set the Max trimpot

at about 50% rotation.

2.

Input a 4 ma. current signal to the control and turn the Min trimpot CW to your desired minimum output voltage or to deadband

(the point just before you begin to get an output).

3.

Input a 20 ma. current signal to the control and set the Max trimpot to the desired maximum speed setting.

4.

With 20 ma. still going to the control, turn the Linearity trimpot CCW until your output speed starts to decrease. Then slowly

turn it back CW until you just reach your maximum speed setting.

For enclosed models use -7 option.

Input impedance: 500 ohms or less

This option replaces the speedpot with a 4-20 ma. signal to control speed. The current signal input can be either grounded or

ungrounded. The board sets on spacers screwed to terminals P1-3, P1-4, and P1-5 on the main board using long screws. The

current source connects to the + and - two position terminal strip (P16-1 and -2) on the -5 option board.

The Linearity trimpot on the -5 option board is set at the factory for proper linearity, however this trimpot may need to

be re-set after tuning the controls Max and Min trimpot settings for your specific application. If needed then refer to the setup

procedure below.

4 to 20 mA .......... -5

DO NOT USE TRIMPOT CHART TO

ADJUST MIN AND MAX TRIMPOTS

ON MAIN BOARD. IF ADJUSTMENT

IS NEEDED THEN REFER TO THE

SETUP PROCEDURE BELOW.

* Note:

This jumper wire is not used with some options. Consult factory if more than one option is being wired. Using the JU2 jumper

wire when not required may cause permanent damage to the control.