MONTHLY

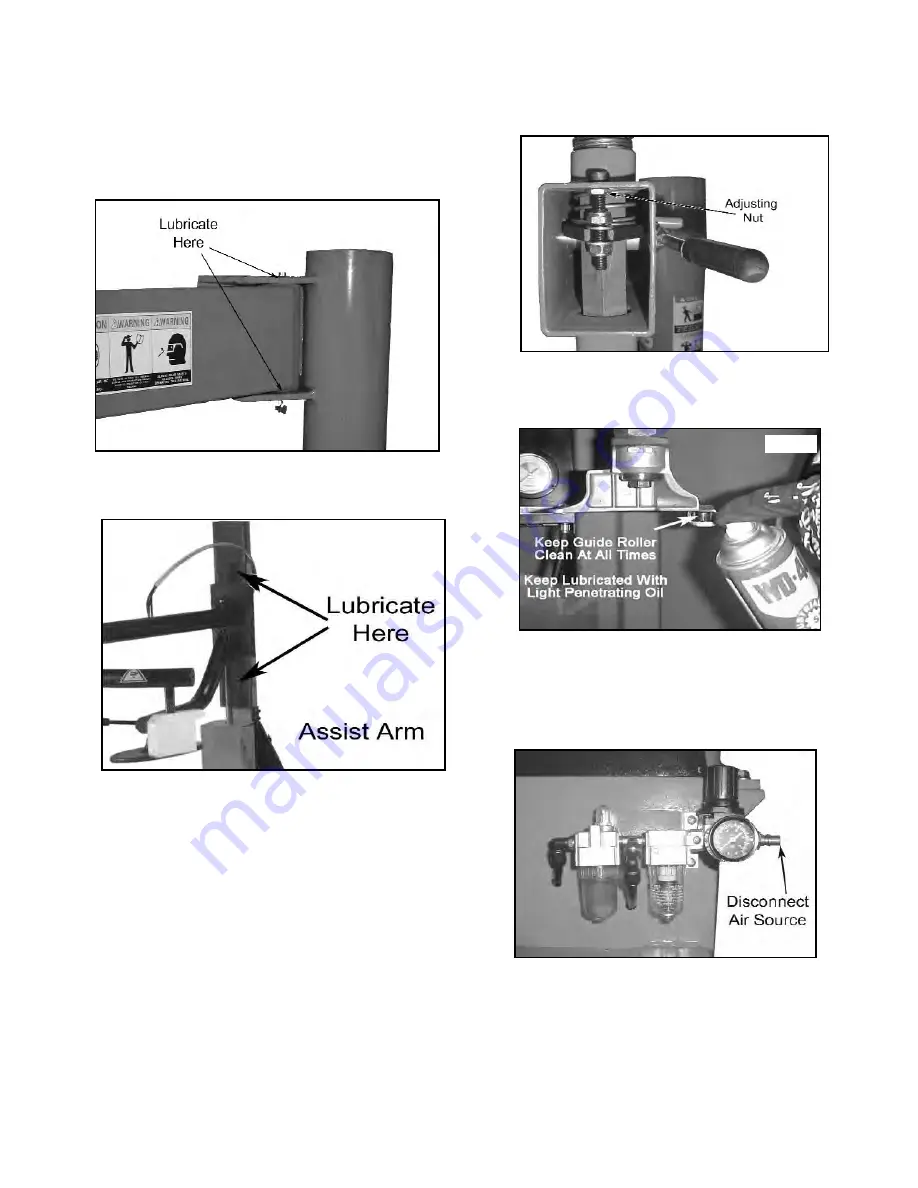

Lubricate the arm Pivot Pin. If so equipped, the vertical

slides should be cleaned with a vaporizing solvent and then

lubricated with chassis grease once a month.

(See Fig. 1-2)

Check adjustment of the mount/demount head monthly.

Check function of the inflation hose pressure limiter/

regulator monthly. Always secure/stow the cover if

adjustments are made.

The pressure regulator should

never be adjusted to exceed 60 PSI.

The table top, clamps, steel mount/demount head, and

other working surfaces should be cleaned with a vaporizing

solvent every month.

On a daily basis, inspect the unit and check to be

certain that all systems are operating normally. Follow

detailed inspection and testing procedures as specified for

various components at regular intervals.

Replace any damaged or missing safety decal's. They

are available from the factory.

Mount/Demount Tool Head Adjustment

To adjust tool head lift, adjust locking nut up or down until lift

clearance is 1/8" to 3/16". Recheck clearance before

replacing cover. (See Fig. 3)

Mount/Demount Head Cleaning

Clean dirt and debris from the mount/demount tool roller

with small screw driver or pick. (See Fig. 4)

Water Separator/Lubricator Maintenance

Check oil and water levels regularly, and perform these

maintenance items weekly:

Disconnect air supply to machine. (See Fig. 5)

Observe the sight glass on the water separator/filter

unit. If water is observed, drain by pressing upwards on the

drain plug at the bottom of the reservoir. (See Fig. 6)

Add oil to the lubricator if the fluid level is below the

middle of the sight glass. Remove the reservoir by turning

counter-clockwise and pulling down. Add SAE 10W non-

detergent oil or an air tool oil if necessary.

22

Fig. 1

Fig. 2

Fig. 3

Fig. 5

Fig. 4

Note: Air Fitting Not Included

Summary of Contents for T-100

Page 1: ......

Page 2: ......

Page 5: ......

Page 6: ......

Page 8: ......

Page 9: ...Note Air Fitting Not Included...

Page 10: ......

Page 14: ......

Page 24: ...24...

Page 25: ......

Page 30: ...14 Insert cone attachment into fitting 15 Secure with pin 16 See final unit assembled...

Page 31: ......

Page 56: ......