9

SEQUENCE OF

OPERATION

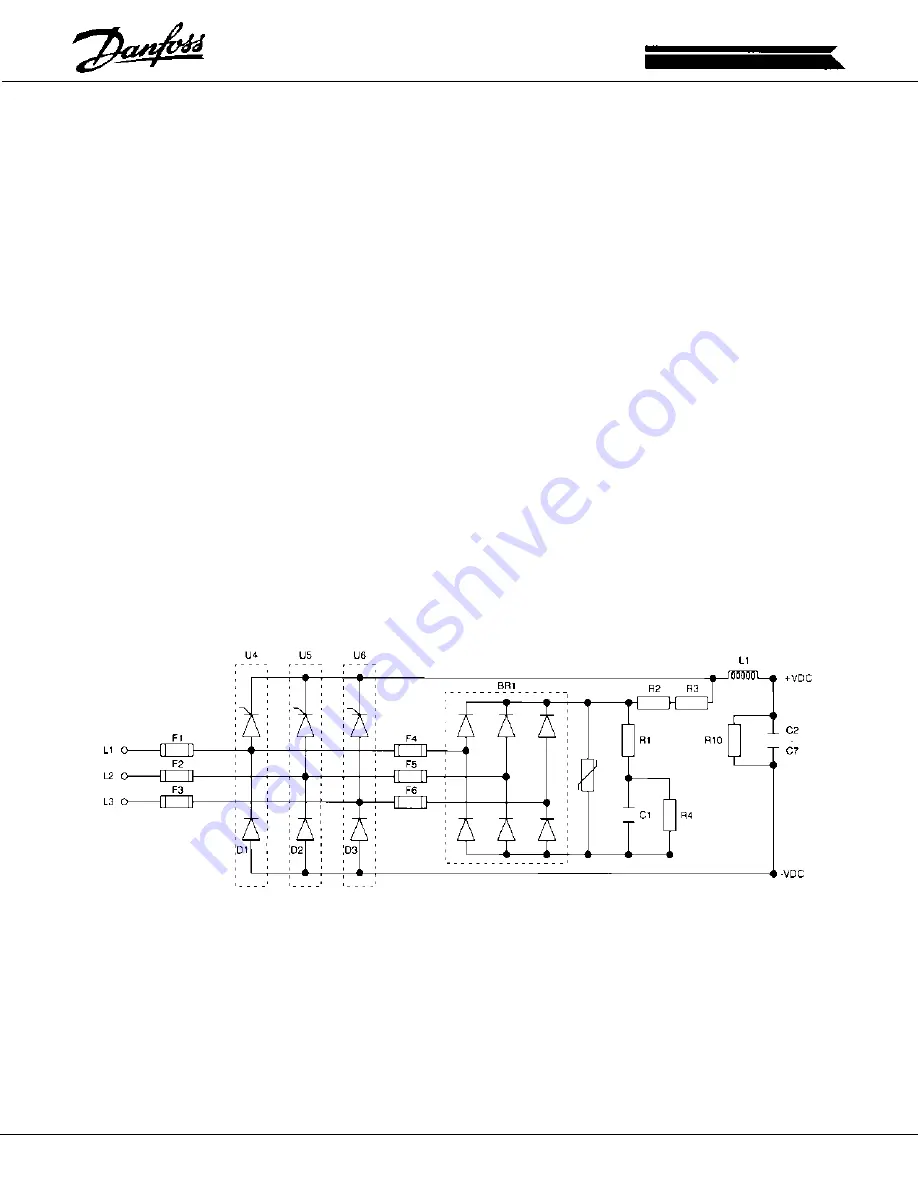

When input power is first applied, the SCR/Diode modules (input

rectifiers) are not gated so the incoming line voltage is rectified by the

soft charge rectifier (BR1). As the DC Bus capacitors charge, the inrush

current is limited by the series soft charge resistors (R2 and R3).

Following a time delay of approximately one second, the interface board

monitors the DC Bus voltage and, providing it has reached an acceptable

level, begins sending gate pulses to the SCR/Diode Modules. Once

the SCR's have been gated on, they remain in this state and the SCR/

Diode modules act as a normal rectifier. This scenario will only be

interrupted if the DC Bus fails to charge. This can be caused by

insufficient line voltage, a fault in the Power Section, a fault in the soft

charge circuit, and also by an open connection at PINS 1 and 2 of

MK15. The SCR Disable input at MK15 is provided as a means to

disable the SCR/Diode modules in the case of an external failure such

as in the Dynamic Brake option. Note that although the SCR/Diode

modules may be disabled, line voltage is still applied to the unit through

the soft charge circuit.

Providing the charging process proceeds normally, the power supplies

will come up and provide the control card and all other sections of the

unit with low voltage control power. At this time the display in the

control card will indicate the unit is ready for operation.

Following a run command and a speed reference, the control card

delivers the PWM signals (one for each phase) to the interface board.

The interface board in turn receives these three signals and creates

the six individual gate drive pulses. The gate drive pulses are sent to

the respective gate drive circuits located on the gate drive card. From

here the output power devices (IGBTS) are switched on and off to

develop the PWM waveform which is ultimately delivered to the motor.

As the unit operates, the interface board monitors the status of the

units operating condition. Currents in excess of limits, temperatures

being exceeded, and voltages out of specification will result in the

interface board responding with a fault and sending the appropriate

fault message to the control card. When a fault occurs, the interface

board will indicate the condition via a series of LED's. The control card

will also display a fault message, and in virtually all cases trip the unit

off line. Section 2 of this manual describes the fault LED's and

messages and provides direction in determining the cause and the

solution for the fault condition.