Instruction

Membrane cleaning of the RO-system with iSave unit

2

180R9214 / 521B1165 / DKCFN.PI.003.G2.02 / 03.2011

Membrane cleaning

Below procedures are general guidelines for the membrane cleaning of SWRO-systems with the

Danfoss iSave. Procedure details may differ depending on the system design.

The numbers marked in () refer to the diagram’s below.

The purpose of membrane cleaning is to reduce scaling and fouling in the membranes. For optimal

performance specific chemicals are required, depending on the cause of the contamination.

After chemical treatment the system must be flushed with fresh water. The flushing water, coming out

of the membranes, may consist of a large amount of suspended inorganic particles. It is important to

assure that these particles are not fed into the iSave.

NB! It is recommended to disconnect the piping from the “HP in” of the iSave and flush the con-

taminated water from the membranes directly to drain. By disconnecting the pipes there will be

no accumulation of contaminations in the HP-piping and HP-valves.

See P&ID no 2.

The procedures below are based on Dow’s Cleaning and Sanitization: Cleaning steps described in

Dow’s Form No. 609-02090-1005. Other procedure may be used depending on the membranes used.

Below procedure is according P&ID no 1.

1. Stop the high-pressure pump (4), and stop the iSave (11).

2. Stop the seawater supply pump (1).

3. Close valve (9) and open valve (16).

4. Pump mixed cleaning solutions to the vessel at conditions of low flow rate and low pressure to

displace the process water. Use only enough pressure to compensate for the pressure drop from

feed to concentrate. The pressure should be low enough that essentially no or little permeate is

produced. A low pressure minimizes re-deposition of dirt on the membrane.

Dump the brine/concentrate to prevent dilution of the cleaning solution.

5. Recycle: After the process water is displaced, cleaning solution will be present in the concentrate/

brine stream. Recycle the cleaning solution from the piping to the cleaning solution tank.

6. Turn of the pump and allow the elements to soak.

Summary of Contents for iSave 21

Page 5: ...User manual iSave 21 5 180R9221 521B1174 DKCFN PS 003 A1 02 1 CE Declaration of conformity...

Page 32: ...User manual iSave 21 32 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 38: ...User manual iSave 21 38 180R9221 521B1174 DKCFN PS 003 A1 02...

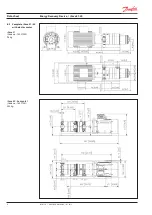

Page 43: ...User manual iSave 21 43 180R9221 521B1174 DKCFN PS 003 A1 02 10 3 Data sheet...

Page 44: ...User manual iSave 21 44 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 58: ...User manual iSave 21 58 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 59: ...User manual iSave 21 59 180R9221 521B1174 DKCFN PS 003 A1 02 10 4 iSave part list...

Page 60: ...User manual iSave 21 60 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 61: ...isave danfoss com iSave 21 Parts list 180R9209 DKCFN PC 003 A2 02 Parts list...

Page 66: ...Parts list iSave 21 Parts list 6 180R9209 DKCFN PC 003 A2 02 03 2011 Exploded view Vane pump...

Page 68: ...Parts list iSave 21 Parts list 8 180R9209 DKCFN PC 003 A2 02 03 2011 Exploded view iSave...

Page 70: ...User manual iSave 21 70 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 71: ...User manual iSave 21 71 180R9221 521B1174 DKCFN PS 003 A1 02 10 5 iSave overload protection...

Page 72: ...User manual iSave 21 72 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 80: ...User manual iSave 21 80 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 82: ...User manual iSave 21 82 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 86: ...User manual iSave 21 86 180R9221 521B1174 DKCFN PS 003 A1 02...

Page 104: ...User manual iSave 21 104 180R9221 521B1174 DKCFN PS 003 A1 02...