Instruction

INFOCAL 8

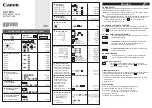

Handle the temperature sensors carefully!

The sensor cables are fitted with coloured type labels:

Red (TH): sensor in hot line,

Blue (TC): sensor in cold line

Make sure the sensors are mounted symmetrically (both directly

immersed, or both installed in a pocket). The maximum cable length

is 10 m. The connecting cables must not be shortened or extended.

The free temperature sensor can be installed in a ball valve /adapter

or in a conformity tested pocket for this type of sensor. Ensure that the

temperature sensors are permanently connected during operation.

For installation in a ball valve (same for adapter), a 4-piece coupling

set is enclosed in a separate bag. See procedure under item 1…5

on the right. Insert an O-ring in the sensor hole using the mounting

pin supplied.

If the sensor is installed in a pocket, it must be inserted as far as the

bottom of the pocket and then secured. The pockets are best installed

in T-pieces with a 45° or 90° angle. The tip of the pocket must point in

the opposite direction to the direction of flow and must be located

in the middle of the pipe.

The temperature sensors must be sealed after installation in the

pockets.

Connect the sensor cables to terminals as shown below.

- For 2-wire connection to terminal 5-6 and 7-8

- For 4-wire connection to terminal 1/5 - 6/2 and 3/7 - 8/4

Calculator type

Sensor

marking

Wiring

2-wire

sensor

Wiring

4-wire

sensor

Installation

position

Heating

Red

T

Hot

(5-6)

T

Hot

(1/5-6/2)

Inlet

Blue

T

Cold

(7-8)

T

Cold

(3/7-8/4)

Outlet

Heating / Cooling

Red

T

Hot

(5-6)

T

Hot

(1/5-6/2)

Inlet

Blue

T

Cold

(7-8)

T

Cold

(3/7-8/4)

Outlet

Cooling

Red

T

Hot

(5-6)

T

Hot

(1/5-6/2)

Outlet

Blue

T

Cold

(7-8)

T

Cold

(3/7-8/4)

Inlet

Cable entries:

1: Cable entry for connecting T

Hot

2: Cable entry for connecting T

Cold

Terminals for temperature sensors:

4.0 Installation of temperature sensors

The operation of any violation of this guidance will result in

immediate invalidation of the factory warranty and verification.

Tighten the plug screw with a torque of approx. 12 Nm

Installation in a ball valve:

Installation in a pocket:

Danfoss District Energy

VI.SH.L1.02

DEN-SMT/PL

3