Danfoss

ET4020 Crimp Machine Operator’s Manual

8 | © Danfoss ET4020 Crimp Machine Operator’s Manual | 2022.12.

AQ435956026217en-000101

Calibration

Must do Part I and Part II

WARNING : Maintain clear distance

from all moving parts.

The calibration procedure below will calibrate the Danfoss ET4020 crimp

machine to the original factory setting. While new machines are calibrated

at the factory and will be ready to use out of the crate, this procedure

should be followed if the crimp machine has been disassembled or has

had components replaced. The procedure requires the use of an FT1380-

200-M240 die cage, a TTC/Z Series -8 fitting and a TTC/Z Series -12 fitting.

1. CAUTION:

While in the calibration mode, follow the instructions

precisely and press the keys deliberately. If a mistake is made, the

calibration procedure must be started over from the beginning.

Part I

1.

Insert an FT1380-200-M240 die cage.

2.

Press the STORE and ENTER buttons simultaneously, then release. Both

button lights will now be illuminated and will remain so until the

calibration procedure is finished.

3.

Enter in the value of “100” using the keypad. (Don’t hit enter.)

4.

Center a TTC/Z Series -8 fitting (without a hose) in the die cage,

holding the socket or fitting in place with a pencil or other suitable

tool. Crimp the socket by depressing the crimp switch until the

machine retracts by itself, indicating a completed cycle. Allow the

crimp ring to return to the “soft retract” position.

5.

Using a set of calipers, measure the crimp diameter. The preferred

method is to use the average of the four pairs of indentations.

6.

Locate the crimp diameter in Table A, below. Using the keypad, enter

in the three-digit Display Reading that corresponds to the Crimp

Diameter.

Note:

If your Crimp Diameter falls between the numbers shown in Table A,

simply determine or interpolate the Display Reading, since the numbers are

a direct ratio.

Part II

1.

Enter in the value of “400” using the keypad. (Don’t hit enter.)

2.

Center a TTC/Z Series -12 fitting (without a hose) in the die cage,

holding the socket or fitting in place with a pencil or other suitable

tool. Crimp the socket by depressing the crimp switch until the

machine retracts by itself, indicating a completed cycle.

3.

Repeat steps 5 and 6 at left, except use Table B instead of Table A for

the -12 fitting.

4.

After the three-digit Display Reading is entered, the machine will

automatically exit the calibration mode.

Calibration Example

Part I

Crimp a TTC/Z Series -8 fitting and measure the four crimp diameters

around the socket. For example, the diameters measure .942, .946, .945 and

.945 inches, to obtain the average diameter, add the four diameters and

divide that sum total by 4.

(.942+.946+.945+.945)/4 = (3.778 )/4= 0.9445 = 0.945

(round to nearest thousandth)

Look at the Crimp Diameter column in Table A and find your average

diameter. If it falls between two numbers, as this one does, interpolate the

desired setting. In this case, you would enter 045. If your crimp diameter

was .940, you would enter 040; if it was .942, you would enter 042.

Part II

Crimp a TTC/Z Series -12 fitting and measure the four crimp diameters

around the socket. This time, let’s say that the diameters measure 1.247,

1.249, 1.249 and 1.248 inches. Average the measures by adding the four

diameters and dividing that sum total by 4.

(1.247+1.249+1.249+1.248)/4 = (4.993)/4 = 1.24825 = 1.248

(round to nearest thousandth)

Look at the Crimp Diameter column in Table B and find your average

diameter. If it falls between two numbers, as this one does, interpolate the

desired setting. In this case, you would enter 348. If your crimp diameter

was 1.250, you would enter 350; if it was 1.249, you would enter 349.

!

!

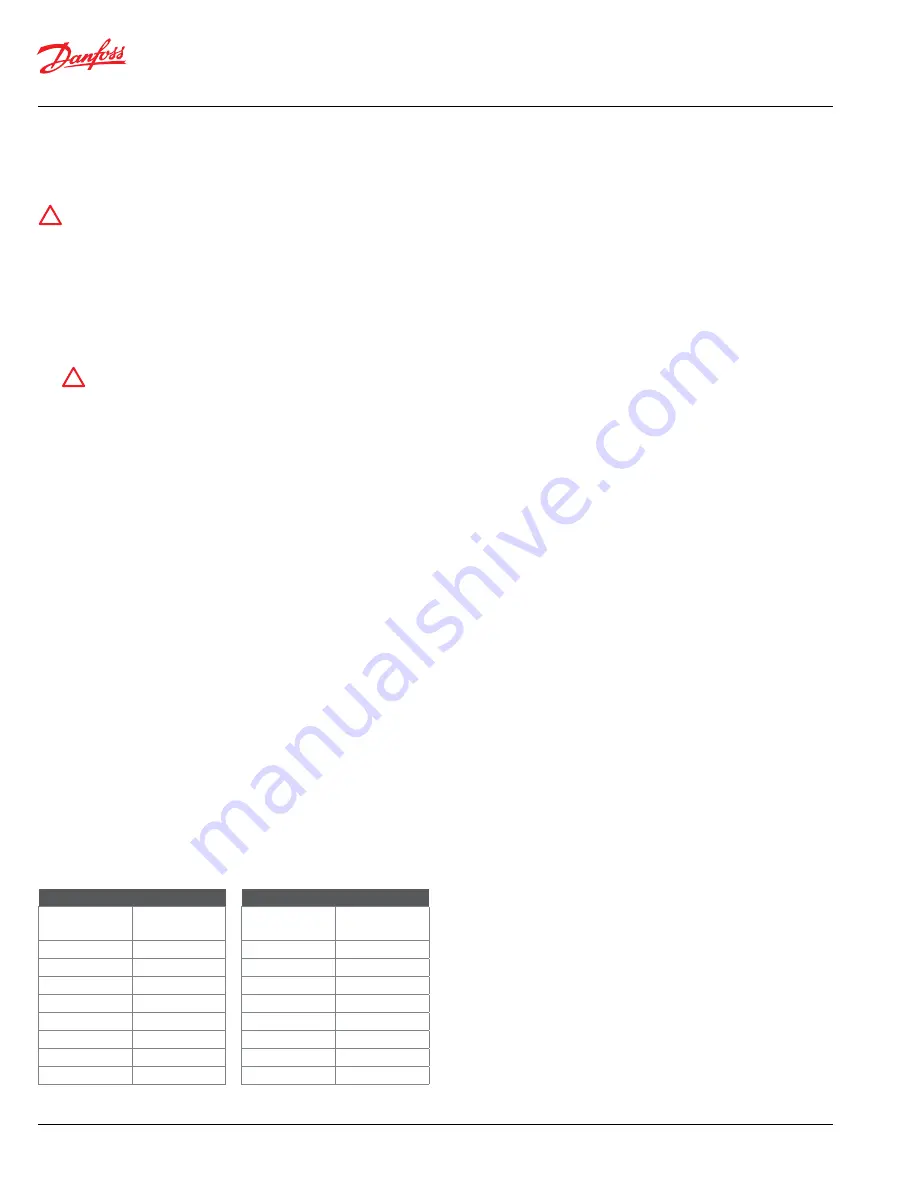

Table A for -8

Crimp Diameter

Display

Reading

0.940

040

0.950

050

0.960

060

0.970

070

0.980

080

0.990

090

1.000

100

1.010

110

Table B for -12

Crimp Diameter

Display

Reading

1.240

340

1.250

350

1.260

360

1.270

370

1.280

380

1.290

390

1.300

400

1.310

410