2

Application guide RA8AB102 © Danfoss 10/2010

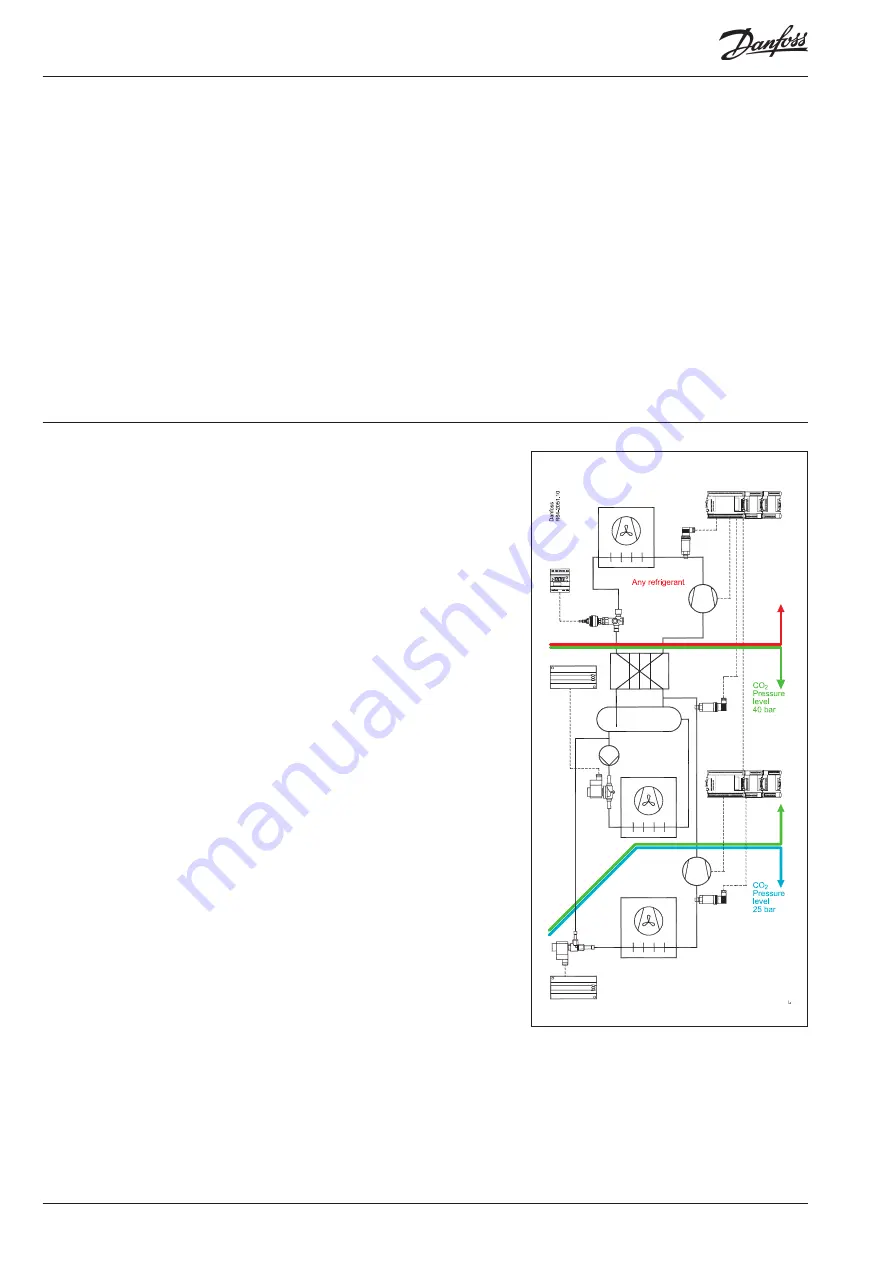

Cascade HC/HFC - CO2 system

Intermediate temperature in a cascade system is

selected based on the required temperature for

high temperature cases in a store which means

they can be cooled by CO2 directly. Intermediate

temperature can also be optimised for the high-

est energy efficiency if the system is used for low

temperature only.

Since a cascade system actually consists of two

different refrigeration systems which are inter-

faced but isolated at the cascade heat exchanger,

the design working pressure for each can be

different. CO2 design pressure is normally based

on the availability of components and is equal to

40-45 bar (corresponding to +5 - +10°C).

In order to prevent pressure from increasing

above the previously mentioned measurements,

standstill systems are recommended. Safety

valves should have the highest setting. Stand still

pressure can be achieved by raising the desing

pressure to 80-90 bar.

For example:

CO2 side

• System design working pressure (saturated suc-

tion temperature): 40 bar (+5°C)

• Safety valve settings: 36 bar (-10% MWP)

• System emergency relief setting: 34 bar (-1°C)

• CO2 discharge pressure setting: 30 bar (-5°C)

The higher the efficiency of the cascade heat

exchanger, the lower the difference between

the condensation temperature of CO2 and the

evaporating temperature of the refrigerant on

the high temperature side. As the temperature

difference on the cascade condenser increases,

the overall efficiency of the refrigeration system

decreases!

General description

Temperatures and pressures

in cascade systems

Ammonia/CO2 cascade systems have the highest

efficiency of all. If HFC is to be used at a high tem-

perature stage, R134a is a preferable option due

to its thermo dynamical properties and lower

(compared to R404A) GWP potential.

Cascade systems are typical not used in FR ap-

plications with traditional refrigerants. There are a

few reasons for this such as the need to maintain

two different refrigerants in one system; system

control strategy (especially that of a cascade heat

exchanger) is more complex. At the same time

using CO2 in cascade systems gives a number of

advantages:

• Efficiency of the system is high even in the hot

climates

• Only a small amount of refrigerant is needed for

high temperature stage

• Temperature difference for cascade heat ex-

changer is relatively low

• On the high side various refrigerants can be

used ex HC/HFC or NH3.

EKC 313

AK-CC 550

AK-CC 450

AK-PC 740/780

AK-PC 740/780