AK-CT

450A

User

Guide RS8GR602 © Danfoss 2016-10

17

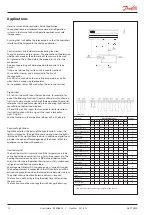

AO1

Analogue output signal, 0-10 V

The signal will follow the EVR valve’s degree of opening

(OD=0% will display 0 V and OD=100% will display 10 V).

The output can be used to control one e.g. 6 minutes modulating

valve.

DI1-DI6

Digital input signal.

The defined function is active when the input is closed/opened.

DI7-DI8

Digital input signal.

The defined function is active when the input receives 230 V.

(Forced closing is, however, active at 0 V)

Data communication

If data communication is used, it is important that the installation

of the data communication cable is performed correctly.

See separate literature No. RC8AC…

MODBUS

For data communication.

Terminal 133 = B-

Terminal 134 = A+

Terminal 135 = screen

RS485 (terminal 130, 131,132)

For data communication, but only if a data communication

module is inserted in the controller. The module can be a LON

RS485.

Terminal 130 = B (B-)

Terminal 131 = A (A+)

Terminal 132 = screen

(For LON RS485 and gateway type AKA 245 the gateway must be

version 6.20 or higher.)

EKA Display

If there is be external reading/operation of the controller, display

type EKA 163B or EKA 164B can be connected.

Electric noise

Cables for sensors, DI inputs and data communication

must

be

kept separate from other electric cables:

- Use separate cable trays

- Keep a distance between cables of at least 10 cm

- Long cables at the DI input should be avoided.

Installation considerations

Accidental damage, poor installation, or site conditions, can give

rise to malfunctions of the control system, and ultimately lead to a

plant breakdown.

Every possible safeguard is incorporated into our products to

prevent this. However, a wrong installation, for example, could still

present problems. Electronic controls are no substitute for normal,

good engineering practice.

Danfoss will not be responsible for any goods, or plant compo-

nents, damaged as a result of the above defects. It is the installer's

responsibility to check the installation thoroughly, and to fit the

necessary safety devices.

Special reference is made to the necessity of signals to the

controller when the compressor is stopped and to the need of

liquid receivers before the compressors.

Your local Danfoss agent will be pleased to assist with further

advice, etc.

Connections

Supply voltage

230 V, or 2 neutral, or 3 neutral. 50 Hz.

Neutral

must

be fitted. If neutral is not in place, the controller can

be damaged. During assembly and disassembly, the power supply

must be interrupted).

DO1

Cooling or exhaust port valve

DO2

Defrost cycle or hot gas valve

DO3

Light

DO4

Light 2, compressor 2 or heating element in drip tray

DO5

Night blind or defrost cycle 2

DO6

Rail heat

DO7

Fan

DO8

Fan in economy mode or defrost 3 or drain valve

DO9

Alarm

There is a connection between terminal 100 and 101 in an alarm

situation, as well as when the controller is without voltage.

DOA

Connection of solenoid valve type EVR. The coil must be half wave

rectified.

S2

Not used

S3, S4, S5, S6

Pt 1000 ohm sensor or PTC 1000 ohm sensor. All have to be of

the same type.

S3, air sensor, placed in the warm air before the evaporator

S3B can be used on appliances with two cooling sections

S4, air sensor, placed in the cold air after the evaporator

(the need for either S3 or S4 can be deselected in

the configuration)

S5, defrost sensor, placed on the evaporator

S5B can be used on appliances with two evaporators,

or on models with long evaporators

S6, product sensor

S6B can be used on appliances with two cooling sections

Pressure transmitter

Not used