Danaher Motion Kollmorgen Speciality Electronics

System Startup

SERVO

STAR

CD-LITE User Manual

11

Feedback

The SERVO

STAR

provides a motor position output to you in the form of quadrature encoder

signals eliminating the need for an additional position feedback device. The outputs are

differential line drivers. There is an associated DC common output (C4: pin 3) which can connect

to your port to keep common mode noise and voltage spikes minimized for device protection.

Because there are normally differences of potential between your controller and the drive,

connection is recommended (if ground loops occur, disconnect and retest).

The source of the Encoder Equivalent Output (EEO) signals depends on the type of motor

feedback device:

This section describes the various feedback types and how they function beginning with firmware version

0.1.8.

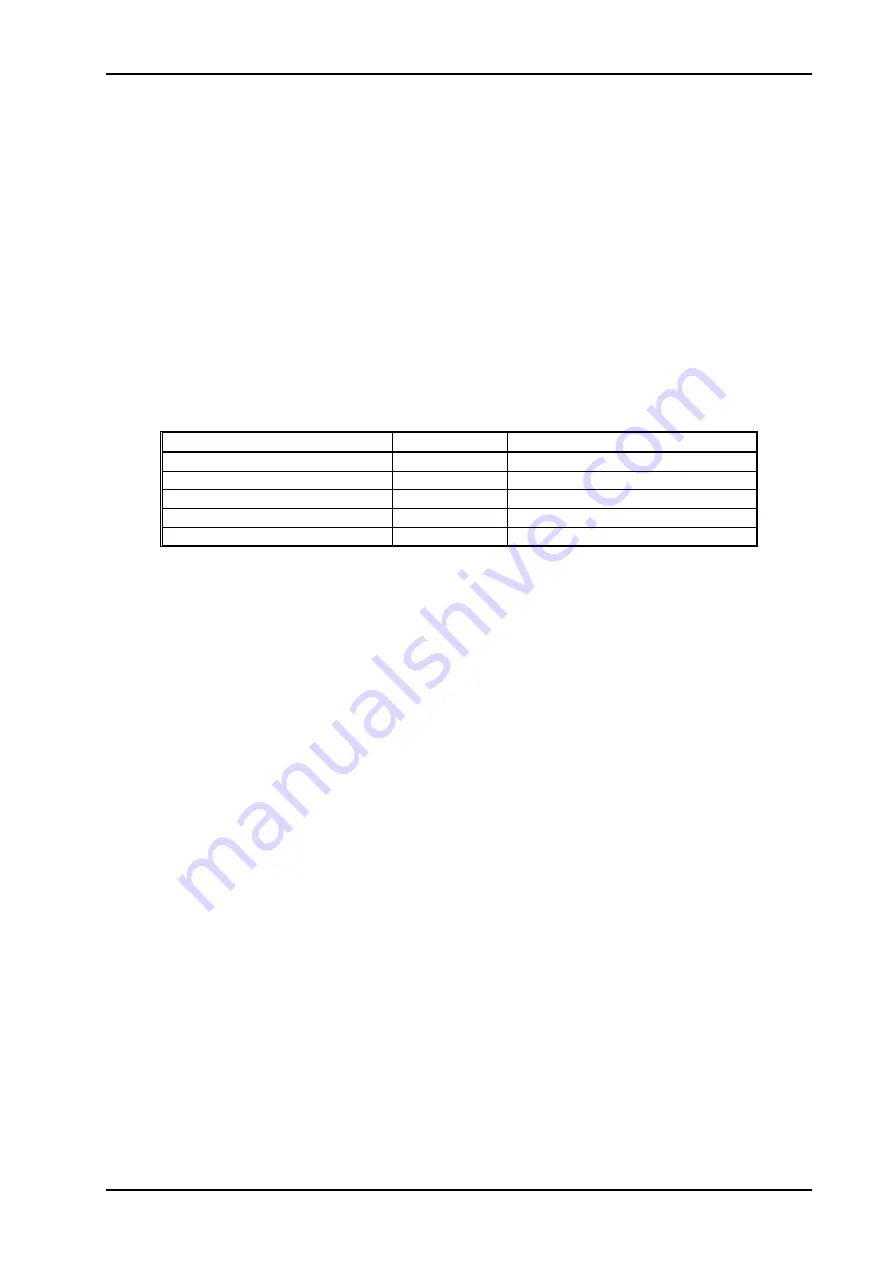

Type MENCTYPE

Comments

Incremental A/B/Z/Halls

0

Incremental A/B/H

6

Resolver NA

Halls only w/ sinus commutation

5

Defined in

MOTIONLINK

Hall only w/ six step commutation

10

Defined by setting DIP switch 2 to ON

Incremental Encoder

The output signal is the actual encoder feedback signal that is pre-configured (MENCRES) in the

drive’s motor parameters. It can be scaled down by multiples of two (ENCOUTO: 1, 2, 4, 8, 16)

and has a maximum frequency limit of 3 MHz.

The SERVO

STAR

can use encoder feedback to monitor the motor shaft position. As opposed to

a resolver, which is an absolute position feedback device, the encoder is an incremental device

that indicates changes in position. The encoder resolution of the SERVO

STAR

(and therefore

the drive’s encoder equivalent output) is fixed because it is a hardware characteristic of the

encoder device. The encoder interface includes three groups of wires:

1.

A/B (and complements) lines make up the encoder quadrature signals. The signals are

received differentially through line receivers before being passed through a wire-break

detection circuit.

2.

The narrow Index pulse normally appears once per revolution and indicates a known

physical position of the shaft. This pulse is received differentially through a line receiver

before being passed through a wire-break detection circuit. This signal is hardware-

capturable.

3.

Hall signals provide information representing the approximate absolute location of the

motor shaft. From this information, the motor can sinusoidally commutate forward until

the index signal is detected - at which time, true position is known. These signals are

isolated by an opto-coupler and can be differential or open-collector type signals.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com