www.dalemans.com

DAT420_MAN02_EN.docx • V1R1

8

DAT 420

6.2

CALIBRATION FOR TOXIC GASES

NO

2

: for DAT 420 detectors fitted with a 0-20 ppm or 0-50 ppm nitrogen dioxide sensor,

use a calibration gas composed of NO

2

at 20 ppm in air!

1.

During adjustment, avoid touching the transmitter circuit or its components with your fingers.

2.

Allow the detector to be powered for at least 24 hours beforehand.

3.

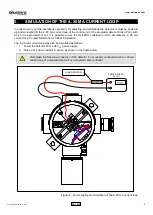

Position the calibration mask and connect the cylinder of nitrogen, the flowmeter and the voltmeter as

shown above.

4.

Adjust the flow rate to between 0.4 and 0.6 l/min and apply nitrogen until the voltmeter display has

stabilised (min. 2 to 3 minutes).

5.

On the transmitter, adjust the "

ZERO

" potentiometer (figure below) to obtain

40 mV ± 0.1 mV

on the

voltmeter.

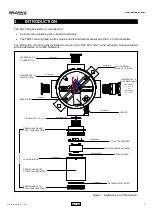

Figure 7 : Calibration for toxic gases

6.

Stop applying nitrogen and wait until the 40…200 mV output signal is completely stable.

7.

Replace the nitrogen cylinder with the cylinder of calibration gas and apply gas at a rate suitable for

the type of gas being used (see Table 2 - page 11). Wait until the voltmeter reading is completely

stable (see "Exposure" in Table 2 - page 11).

8.

Adjust the "GAIN" potentiometer (figure above) to obtain a reading on the voltmeter corresponding to

the ratio between the calibration gas and the target measuring range.

This value is given, in mV, by the following formula :

10

4

4

20

×

+

−

×

=

Range

Gas

CAL

Measure

V

CY

REGULATOR

VOLTMETER

mV

═

+

-

+

-

"GAIN"

POTENTIOMETER

"ZERO"

POTENTIOMETER

V

Measure

.

ZERO

GAIN