NPN-410X Series Border Installation Quick Guide

Page 1 of 1

DD3838321

Rev 02

12 July 2019

201 Daktronics Drive

Brookings, SD 57006-5128

www.daktronics.com/support

800.325.8766

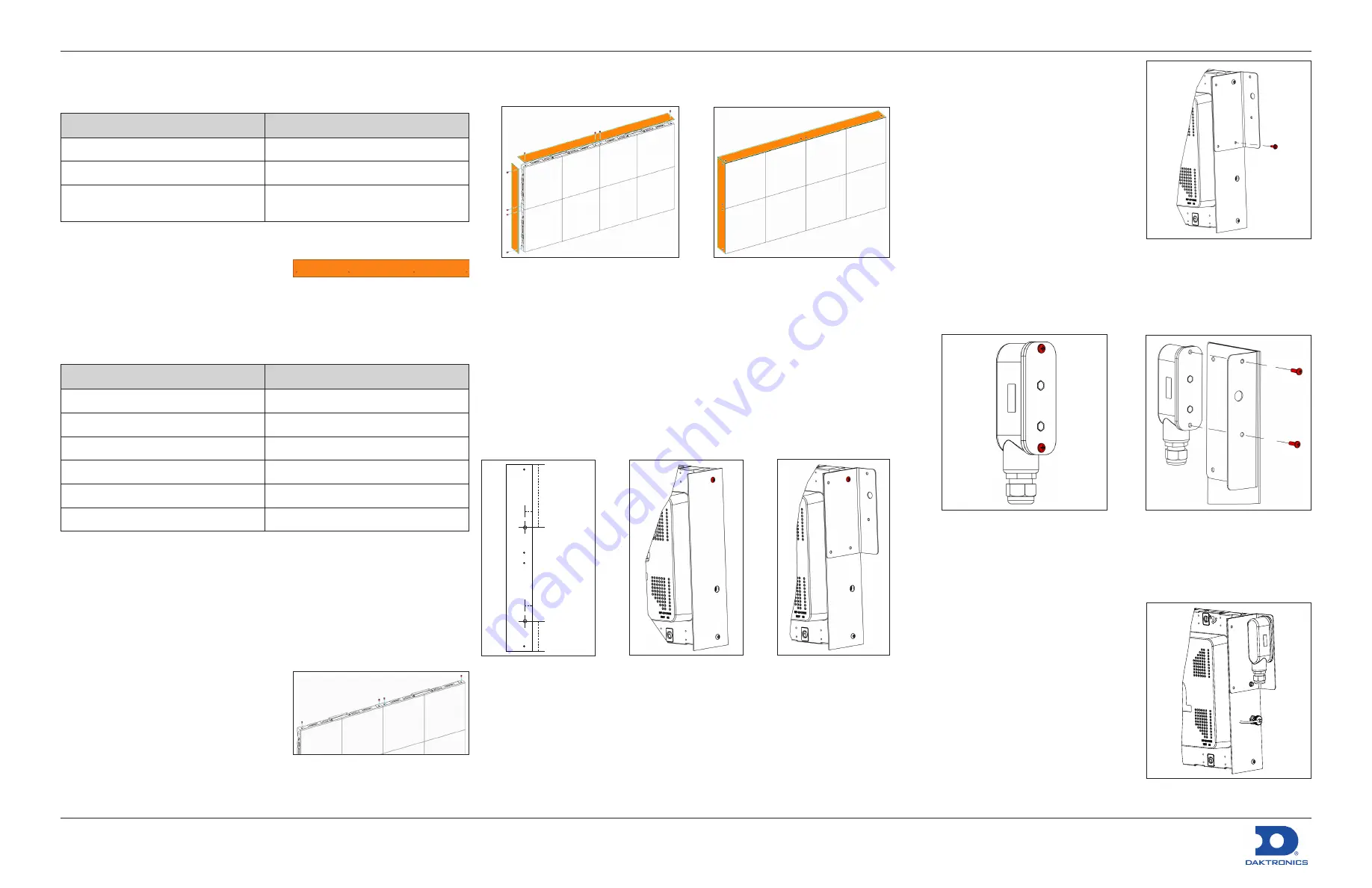

Flat Border

Tools

Part

Part Description

Cordless screw gun

Attaches borders to section

Flat-head bit or screwdriver

Removes top alignment pins

T-25 TORX

®

bit (Daktronics part number

TH-1118)

Attaches borders

Identify Part

There are six different border sizes for

the NPN-410X display series: one-, two-,

three-, and four-module-high borders

and two- and four-module-wide

borders. The part numbers are etched into the metal on each border for

identification purposes. Refer to the table below for part numbers and to

Figure 1

for a visual.

Part Number

Part Description

0M-3807592

Flat Border, Side, 1-High

0M-3807594

Flat Border, Side, 2-High

0M-3807596

Flat Border, Side, 3-High

0M-3807598

Flat Border, Side, 4-High

0M-3807600

Flat Border, Top/Bottom, 2-Long

0M-3807602

Flat Border, Top/Bottom, 4-Long

Install Border

Borders are attached either before the display is mounted to the structure

or after if site conditions allow for tool clearance around the mounted

display. If the borders must be installed before the sections, only

one-module-high (Daktronics part number 0M-3807592) and

two-module-wide (0M-3807600) borders are available. Borders longer than

one module high or two modules wide must be installed after the display

sections are mounted to the structure.

1.

Remove the top alignment pins

from the top row of panels. Refer to

Figure 2

.

2.

Select the correct border size

according to the Shop Drawing.

3.

Use a clean rag to wipe off the

perimeter of the panel receiving the

border.

Figure 1:

Flat Border

Part number

Figure 2:

Prepare Top Row of Panels

4.

Bring the border into position. The holes should be oriented toward the

front of the display to align with the threaded holes in the panels. Refer

to

Figure 3

.

Figure 3:

Install Flat Border

Figure 4:

Attached Flat Border

5.

Use a

1

/

4

" T-25 TORX

®

bit (TH-1118) to remove the M5-0.8 x 10 mm

machine screws (HC-3809581) to fasten the border to the panel

perimeter in all pre-punched hole locations on the border. Each panel

has threaded holes for borders on all four sides. Refer to

Figure 4

for the

finished appearance.

Light Sensor

Install Mounting Bracket

Border modifications are required for light sensors. Drill a 0.5" diameter hole

1" from the front of the border and either 9.132" from the top of the border

or 4.375" from the bottom. Refer to

Figure 5

and

DWG-3898915

for details.

Figure 5:

Modify Border

for Light Sensor

Front of

border

1"

9.132"

4.375"

1"

Figure 6:

Remove

Machine Screw

Figure 7:

Position

Mounting Bracket

1.

Use a

1

/

4

" T-25 hex bit (TH-1118) to remove the M5-0.8 x 10 mm machine

screw (Daktronics part number HC-3809581) above the panel mount

location and set the screw aside for

Step 2

. Refer to

Figure 6

.

2.

Position the mounting bracket on the border, aligning the top-right

hole of the bracket with the hole on the border where the screw was

removed in

Step 1

. Use a

1

/

4

" T-25 hex bit (TH-1118) to secure the

M5-0.8 x 10 mm machine screw (HC-3809581) from

Step 1

into the hole.

Refer to

Figure 7

.

3.

Use a

5

/

16

" socket/driver to install a

#10-16 x 0.75 TEK screw (HC-1530)

through the bottom-right hole in the

bracket. Refer to

Figure 8

.

Install Light Sensor

Refer to

DWG-3898915

,

DWG-3887723

, and

the steps below for installation details.

1.

Ensure the display is physically mounted

with power and signal installed.

2.

Ensure power is disconnected from the

display.

3.

Mount the light sensor in a suitable

location.

a.

Use a Phillips screwdriver to remove the two #8-32 x 0.500 machine

screws (HC-1144) in the light sensor and set the screws aside for

Step 3.b

. Refer to

Figure 9

.

Figure 9:

Remove Light Sensor

Screws

Figure 10:

Position Light Sensor on

Mounting Bracket

b.

Position the light sensor on the flange of the mounting bracket and

secure the sensor in place with the two screws from

Step 3.a

. Refer

to

Figure 10

.

4.

Locate the PLR closest to the light

sensor mounting location and connect

the light sensor. Only one light sensor

can be connected to each PLR.

a.

Connect the four-pin plug

(W-3884831) to the PLR.

b.

Mount the panel mount M12 jack

(W-3884831) per

DWG-3898915

.

Wrap and secure the excess cable.

5.

Connect the light sensor harness

(W-2532) to the panel mount M12 jack

installed in

Step 4

. Refer to

Figure 11

.

6.

Secure the cables as needed.

Figure 8:

Install TEK Screw

Figure 11:

Connect Light Sensor

to Panel Mount Jack

Summary of Contents for NPN-4100 Series

Page 4: ...This page intentionally left blank...

Page 8: ...This page intentionally left blank...

Page 10: ...This page intentionally left blank...

Page 14: ...This page intentionally left blank...

Page 16: ...This page intentionally left blank...

Page 18: ......

Page 20: ......

Page 28: ......

Page 30: ...This page intentionally left blank...