10

Environmental conditions

46°C

90% max

The machine was designed to operate in technical spaces or outdoors. It

CANNOT

operate

in environments with

explosive material

, high concentration of

dust

and in environments

with

high temperatures (range from -25 to 46°C - maximum altitude: 2500 m above

sea level),

unless specific production requests were made.

These machines are used to resolve thermohygrometric and air purity problems in both civil

and industrial environments.

Thanks to its modularity, each machine is able to adapt to different needs in terms of air

handling:

-

civil

-

airports

-

banking

-

commercial

-

hotel

-

museums, theatres, cinemas and auditoriums

-

television and recording studios

-

libraries

-

data processing centres

The optimised choice of every detail, the search for maximum efficiency in each component, the adop-

tion of specific materials and constructive solutions transform environment friendliness and energy sav-

ings into valid and advanced technological solutions.

Environmental contamination

Depending on the installation operating environment, specific regulations must be followed and all the

necessary precautions must be taken to avoid environmental issues (a system that operates in a hospital

or chemical environment can have problems different from those in other sectors, even from the point of

view of disposal of consumable parts, filters, etc.).

It is mandatory for the buyer to inform and train workers regarding proper procedures.

Controller limit operating conditions

Operation (IEC 721-3-3):

-

Temperature -40 ÷ +70 °C

-

LCD -20 ÷ +60°C

-

Humidity <90% relative humidity (without condensation)

-

Min. air pressure 700 hPa, corresponding to a maximum of 3,000 m above sea level

-

Transport (IEC 721-3-2) and storage:

-

Temperature -40 ÷ +70 °C

-

Humidity <95 % relative humidity (without condensation)

-

Min. air pressure 260 hPa, corresponding to a maximum of 10,000 m above sea level

Machine characteristics

2

Summary of Contents for Modular Plate

Page 15: ...15 Notes...

Page 28: ...28 Notes...

Page 33: ...33 VDI 6022 6...

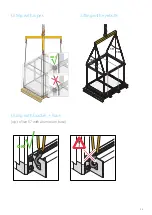

Page 34: ...34 1 x TE8x35 1 x 8 5 1 x M8 2 x TE8x35 2 x 8 5 2 x M8 7...

Page 43: ...43 3 4 5 x 1 100mm 100mm 250mm 250mm 250mm 10 100mm 5mm...

Page 44: ...44 6 7 NO OK...

Page 45: ...45 H2O SOAP 8...

Page 46: ...46 9...

Page 47: ...47 Notes...

Page 62: ...62 Repair log DATE SERVICE TYPE TIME REQUIRED SIGNATURE...