www.DaikinApplied.com 65

IM 830-6

Unit Ventilator(s) Start-up

Remove debris, dust, dirt and any obstruction from the outside

air ducting, return air ducting (if applicable) and discharge air (if

applicable) as this will affect unit performance.

NOTICE

1. Open the bottom-hinged access panels.

Before proceeding, inspect the fan system to be sure that

all parts are aligned properly and move freely. Inspect

fans and fan discharge area for obstructions. Rotate

fans manually. Check that a clean filter is installed and

ductwork to and from the unit ventilator is free of debris.

2. All panels should be in place and properly fastened.

Do not attempt to operate the unit fans until the fan bearings have

been oiled. Oiled bearings provide smooth, and quiet operation of

the fan system.

CAUTION

!

Remove Battery Shipping Tab

Check that board backup battery shipping tab is removed. To

remove, grasp tab and gently pull. Battery should be replaced

every 3 years of unit service.

Remove Battery ShippingTab

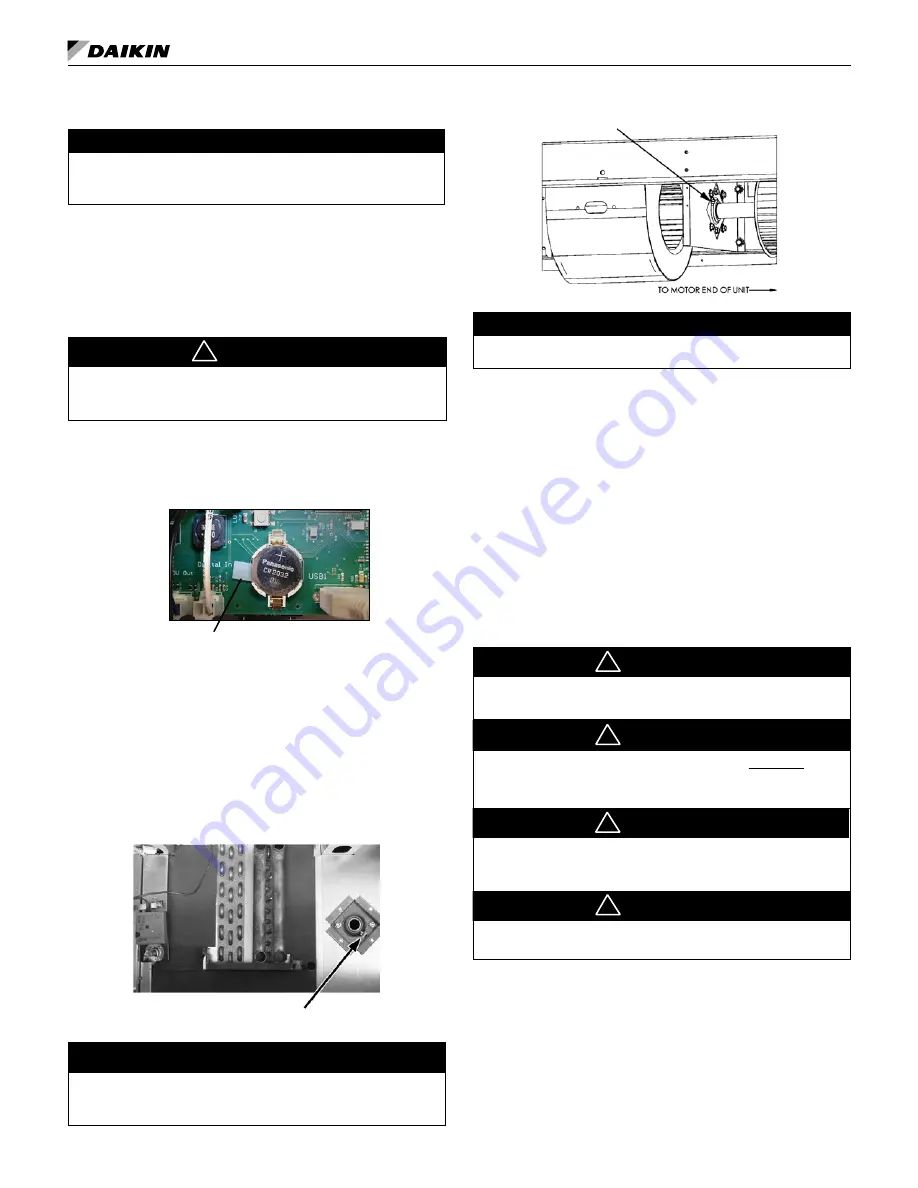

Oiling the Fan Shaft End Bearing

Access to fan shaft bearing is through bottom hinged access

panel, in the units left end compartment (

the oiler cap. Oil, using a few drops of high grade SAE 20 or

30 non detergent oil. Periodically oil the bearing every 6-12

months to maintain proper lubrication.

Figure 104: Oiling Point

Note:

Access to the Fan Shaft Bearing Through the Bottom, Large-

Hinged Access Panel. The bearing is located at the Left End

of the Unit.

Bearing Oiler Cap

For 1500 and 2000 cfm units, access to the fan shaft bearing is

through the bottom hinged access panel. It is located between

the third and fourth fan housing from the right (

).

NOTICE

Figure 105: Oiling Point for 1500 and 2000 cfm units

Bearing Oiler Cap

NOTICE

G.E. motor manufacturer recommends not oiling the fan motor.

Start-up Procedure

1. After the unit ventilator has been properly installed,

activate unit electrical power and applicable chilled water/

hot water/steam/refrigerant systems.

2. Using the applicable control, activate the unit ventilator.

Depending on the operating mode selected, the dampers,

fans, and other components should operate as needed.

3. Run the unit ventilator for ten minutes, listening and

observing. Fans should be operating correctly and rotating

in proper direction, without unusual noise. Likewise,

the unit should be free of sheet metal rattles and / or

unusual noises. All panels should be in place and properly

fastened. Check for air leaks and condensation.

Filter Access and Removal

With Daikin’s single-filter design, filter change out takes only

minutes.

Turn off unit before servicing to avoid danger of electric shock, and

injury from moving parts.

CAUTION

!

Units must have a filter installed when operating. Operation without

a filter can compromise unit performance due to build up of dust and

dirt on components.

Dirty or clogged filters can impact unit performance, resulting in

damage to the unit.

Electric heat units should ONLY use permanent wire mesh filters.

Filters other than wire mesh are not intended for electric heat units,

and can cause unit damage, property damage or personal injury.

CAUTION

!

CAUTION

!

CAUTION

!

Turn off the unit, (fan speed switch or unit on/off switch is

located behind the bottom access panel, located in the right

end compartment).

The AH Model filter is removed by fully opening the bottom,

louvered hinged access panel (

). Release the ends of the safety chains (2) attached

at the unit frame to allow full swing of the louvered panel (

). Loosen (do not remove) the two (2) hex head screws on the

slotted filter bracket, and slide the –filter bracket away to provide