Si041411E

Electrical Box / PCBs

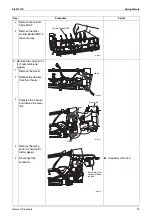

Removal Procedure

9

5. Electrical Box / PCBs

Warning

Be sure to wait for 10 minutes or more after turning off all power supplies before

disassembling work.

Step

Procedure

Points

1. Disconnect the

connecting wires.

1

2

Remove the screw and

remove the wire fixture.

Remove the 4 screws

on the terminal board

and disconnect the

connecting wire.

2. Remove the electrical

box.

1

Remove the screw.

2

3

Unfasten the 3 hooks.

Remove the front grille

(front).

4

Unfasten the hook and

remove the shield plate.

Terminal board

Wire fixture

Connecting

wire

(R20716)

(R19834)

Hook

Front grille (front)

(R19835)

(R19836)

Hook

Shield plate