EWAQ+EWYQ009~0 EWAQ+EWYQ009~013ACW1

Packaged air-cooled water chillers and packaged

reversible air to water heatpumps

4PW51587-1A

Installation manual

24

Symptom 5: The water pressure relief valve leaks

Symptom 6: The user interface displays "

n

n

n

n

" when pressing

certain buttons

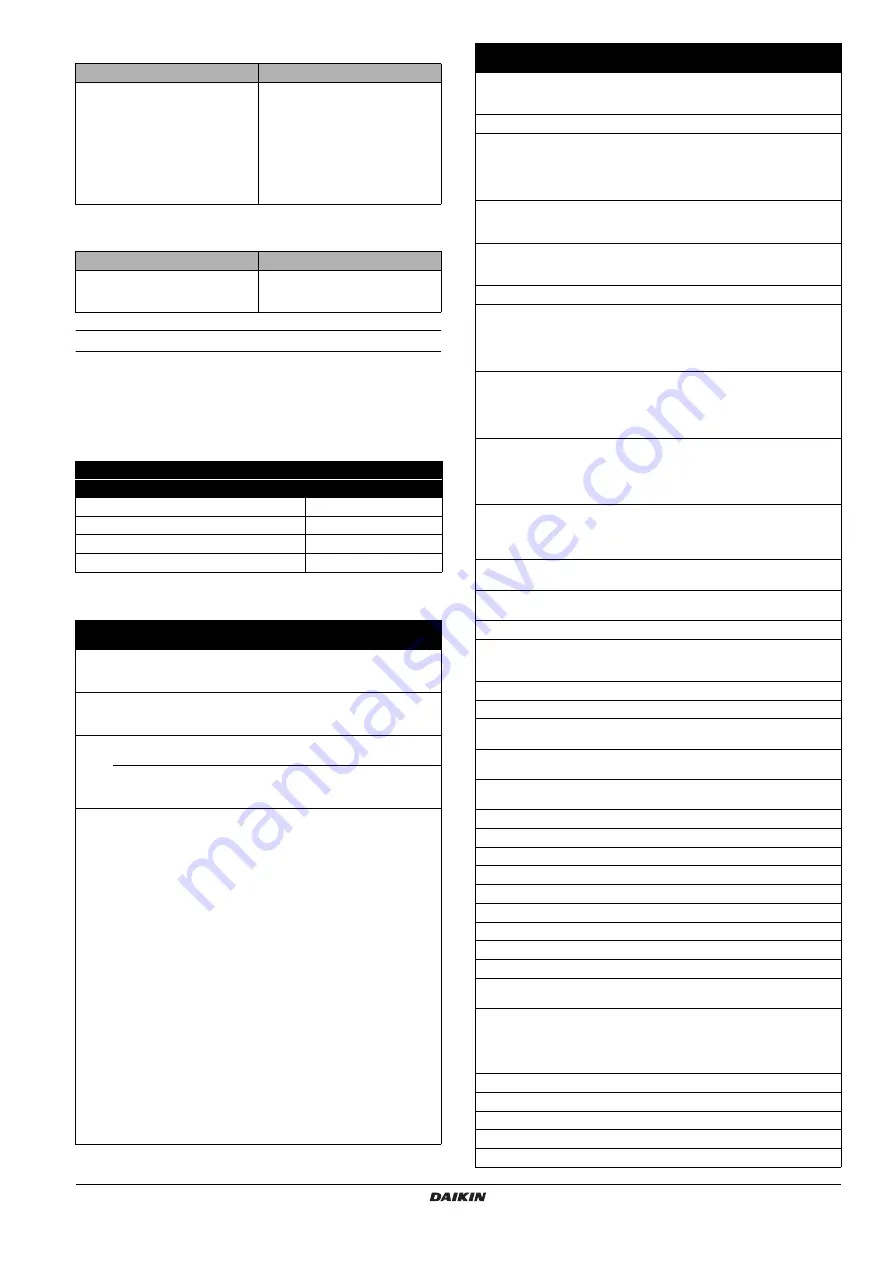

Error codes

When a safety device is activated, the user interface LED will be

flashing, and an error code will be displayed.

A list of all errors and corrective actions can be found in the table

below.

Reset the safety by turning the unit OFF and back ON.

In case this procedure for resetting the safety is not successful,

contact your local dealer.

P

OSSIBLE

CAUSES

C

ORRECTIVE

ACTION

Dirt is blocking the water pressure

relief valve outlet.

Check for correct operation of the

pressure relief valve by turning the

red knob on the valve counter

clockwise:

• If you do not hear a clacking sound,

contact your local dealer.

• In case the water keeps running out

of the unit, close both the water inlet

and outlet shut-off valves first and

then contact your local dealer.

P

OSSIBLE

CAUSES

C

ORRECTIVE

ACTION

The current permission level is set to

a level that prevents using the

pressed button.

Change the "user permission level"

field setting ([0-00], see

Instruction to turn the unit OFF

User interface mode (heating/cooling

=

)

Push the

y

button

ON

1 time

ON

1 time

OFF

—

OFF

—

Error

code

Failure cause

Corrective action

80

Inlet water temperature

thermistor failure (inlet water

thermistor broken)

Contact your local dealer.

81

Outlet water temperature

thermistor failure (outlet water

temperature sensor broken)

Contact your local dealer.

89

Water heat exchanger freeze-up

failure (due to water flow too low)

Refer to error code

7H

.

Water heat exchanger freeze-up

failure (due to refrigerant

shortage)

Contact your local dealer.

7H

Flow failure (water flow too low

or no water flow at all, minimum

required water flow is 16 l/min)

• Check that all shut off valves of

the water circuit are completely

open.

• Check if the water filter needs

cleaning.

•

Check that the unit is

operating within its operating

range (refer to

• Also refer to

• Make sure there is no air in the

system (purge air).

• Check on the manometer that

there is sufficient water

pressure. The water pressure

must be >0.3 bar (water is cold),

>>0.3 bar (water is hot).

• Check that the pump speed

setting is on the highest speed.

• Make sure that the expansion

vessel is not broken.

• Check that the resistance in the

water circuit is not too high for

the pump (refer to

).

• Check that the pump fuse (FU2)

and PCB fuse (FU1) are not

blown.

8H

Outlet water temperature of unit

too high (>65°C)

Check that the outlet water

thermistor is giving the correct

read out.

A1

Hydraulic PCB defective

Contact your local dealer.

A5

Too low (during cooling

operation) or too high (during

heating operation) refrigerant

temperature (measured by

R13T)

Contact your local dealer.

C0

Flow switch failure (flow switch

remains closed while pump is

stopped)

Check that the flow switch is not

clogged with dirt.

C4

Heat exchanger thermistor

failure (heat exchanger

temperature sensor broken)

Contact your local dealer.

E1

Compressor PCB defective

Contact your local dealer.

E3

Abnormal high pressure

Check that the unit is operating

within its operating range (refer

to

).

Contact your local dealer.

E4

Actuation of low pressure sensor

Check that the unit is operating

within its operating range (refer

to

).

Contact your local dealer.

E5

Overload activation of

compressor

Check that the unit is operating

within its operating range (refer

to

).

Contact your local dealer.

E7

Fan lock failure (fan is locked)

Check if the fan is not obstructed

by dirt. If the fan is not

obstructed, contact your local

dealer.

E9

Malfunction of electronic

expansion valve

Contact your local dealer.

F3

Too high discharge temperature

(e.g. due to coil blockage)

Clean the coil. If the coil is clean,

contact your local dealer.

H3

Malfunctioning HPS system

Contact your local dealer.

H9

Outdoor temperature thermistor

failure (outdoor thermistor is

broken)

Contact your local dealer.

J1

Malfunction of pressure sensor

Contact your local dealer.

J3

Discharge pipe thermistor failure

Contact your local dealer.

J5

Suction pipe unit thermistor

failure

Contact your local dealer.

J6

Aircoil thermistor frost detection

failure

Contact your local dealer.

J7

Aircoil thermistor mean

temperature failure

Contact your local dealer.

J8

Liquid pipe unit thermistor failure

Contact your local dealer.

L4

Electric component failure

Contact your local dealer.

L5

Electric component failure

Contact your local dealer.

L8

Electric component failure

Contact your local dealer.

L9

Electric component failure

Contact your local dealer.

LC

Electric component failure

Contact your local dealer.

P1

PCB failure

Contact your local dealer.

P4

Electric component failure

Contact your local dealer.

PJ

Failure of capacity setting

Contact your local dealer.

U0

Refrigerant failure (due to

refrigerant leak)

Contact your local dealer.

U1

Power supply cables are

connected in the reverse phase

instead of the normal phase.

Connect the power supply

cables in normal phase. Change

any two of the three power

supply cables (L1, L2, L3) to

correct phase.

U2

Main circuit voltage failure

Contact your local dealer.

U4

Communication failure

Contact your local dealer.

U5

Communication failure

Contact your local dealer.

U7

Communication failure

Contact your local dealer.

UA

Communication failure

Contact your local dealer.

Error

code

Failure cause

Corrective action

Summary of Contents for EWAQ-ACV3

Page 29: ...NOTES NOTES ...