【INSTRUCTION MANUAL】

DAIKIN INDUSTRIES, LTD

.

SE-04430

【

8.Test run

】

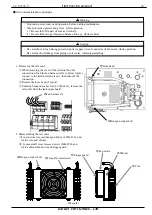

After completing pouring fixed amount of hydraulic oil into tank, piping, and wiring, perform test run.

Starting confirmation

Changing oil

Removing air

Flushing operation

・

After confirmation of the start, perform flushing operation under the circuit

pressure at low pressure. As flushing operation, connect all piping with

loop style except the actuator, and operate through 10

μ

m filter by the oil

tank of the return piping.

・

After completing the flushing operation, remove hydraulic oil in the tank

completely out of drain plug. Then fill fixed amount of flesh hydraulic oil

to the oil inlet port with air breather.

(Within NAS 10 class pure oil is used as flesh hydraulic oil.)

・

Remove the air of hydraulic circuit completely.

If the air has not been removed thoroughly,

①

abnormal operation of actuator, such as cylinder

②

abnormal noise in the pump or in the valve

may occur.

・

Turn the switch of machine controller “ON”.

①

Before power on, confirm wiring of earth properly.

②

It is not abnormal though it may take 12~13 seconds until pressure rises

after power on.

(Refer to Att.11page: 1-1,1-2)

③

Confirm the pump rotation sound and pressure rising.

④

Confirm that the fan of oil cooler is rotating.

16

Danger

・

In the process of air removing, be careful because there is a case of high pressure or high temperature

oil spouts.