19

(TROUBLE 3) No microwave oscillation even though fan motor rotates.

Condition

No

microwave

oscillation

Check

Result

Cause

Remedy

Replace

Check continuity

of high voltage

capacitor

terminals with

wires removed

Continuity

Defective high

voltage

transformer

Replace

Check continuity of

high voltage diode

in forward and

backward direction

with DC megger

Continuity in

backward

diode

Defective high

voltage diode

Replace

Connect megger

leads to

magnetron

terminal and

magnetron body

Continuity

Defective

magnetron

Replace

Check resistance

of primary and

secondary coil of

high voltage

transformer

Defective high

voltage

transformer

Replace

Check continuity

of magnetron

with wires

removed

No

Continuity

Defective

magnetron

Replace

Check continuity

of filament

terminal of high

voltage

transformer

No

Continuity

Defective high

voltage

transformer

Replace

Check D.C.

voltage being

supplied to

RELAY (RY1)

coil

0V

Defective touch

control circuit

Replace

Approx

15 VDC

Faulty contacts of

RELAY (RY1) or

open relay coil

19

Summary of Contents for KOR-6QAB5S

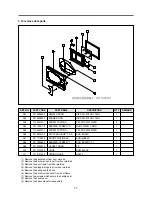

Page 5: ...4 EXTERNAL VIEW 1 OUTER DIMENSION...

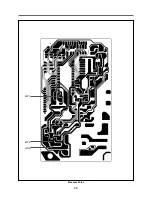

Page 25: ...24 WIRING DIAGRAM...

Page 27: ...26 Measure Point MP1 MP2 GND...